SETTING THE STANDARD IN EVAPORATIVE COOLING MEDIA

Meeting the evaporative cooling pad

needs of all marketplaces

The unique system used for manufacturing KOOL® pads

allows the manufacture of custom flute angle

designs as well as the standard angles.

Applications.

Evaporative Cooling Systems, Precoolers, Humidification, Cooling Towers

Space Coo ling

Hog, Poultry, Ex Houses. Dairy

What is a KÜÜL® pad?

A KÜÜL® pad is the highest quality rigid cooling media on the market today. Specifically, KÜÜL®) pads are constructed with a heavier, virgin quality kraft paper containing a higher resin content which provides effective and efficient cooling while giving KÜÜL® pads greater durability, strength and longevity.

KÜÜL® pads are cellulose cooling cells generally cut in 2″, 4″, 6″. 12″, even up to 24″ thickness, and available in any height up to 78.75″. Ag-Hort KÜÜL®® pads are generally manufactured in 2″, 4″, or 6′ thickness and 78.75″ in height. while the HVAC KÜÜL®® pads are available in up to 78.75 inches in height and 24 inches in width. The cooling media is constructed of a specially formulated paper impregnated with insoluble resin. It is designed with a cross-fluted configuration, which induces highly turbulent mixing between the water and the air inside the pad. The air is bent at angles designed to maximize the evaporative efficiency while offering the least restriction of airflow, The cross-fluted design makes the pad strong, self-cleaning and self-supporting with high evaporative efficiency and low-pressure drop (resistance to airflow). The unique system used for manufacturing KÜÜL® pads allow the manufacture of custom flute angle designs as well as the standard angles.

KÜÜL® pad use – Climate Control

Direct evaporative cooling is most often associated with temperature reduction.

With an evaporative cooling pad, air is drawn through the wet media. The heat exchange occurs as air moves over the layered, fluted surfaces of the wet pad causing water to evaporate off the pad, thus removing heat from the air.

The key in achieving the best performance from an evaporative cooling system is maximizing the amount of air that conies into contact with the cooling pad surface area. Evaporative cooling pads typically produce the most efficient evaporative cooling when they are designed to provide the maximum interaction possible between air and water.

KÜÜL®® pads are the best choice for evaporative cooling systems because .. .

- Made with the heaviest, highest-quality virgin kraft paper in the industry for maximum longevity

- Highest resin content in the industry

- Out-performs the competition in tests:

- High tensile strength, psi

- High dry crush strength. psi

- High wet crush strength, psi

- KÜÜL® pads are the only pads with each individual sheet cured separately

- Cure is consistent and completely established at all

contact points throughout the pad. providing unequaled stability

Available in custom sizes and flute angles

- Specializing in custom flute angles and sizes

Advanced resin technology

- improves strength, longevity, absorption and cooling efficiency

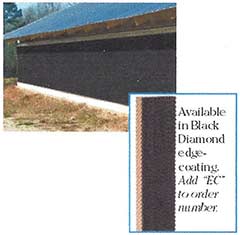

- Most durable edge coating in the

marketplace

KÜÜL® pad service

- Orders processed and shipped promptly

- Custom orders welcomed

- Ongoing product development and research