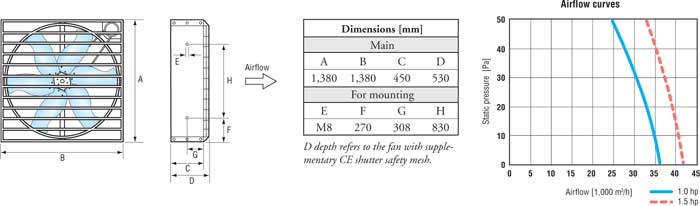

Exhaust Fan EM 50n

Propeller and shutter

Equipment

- Central hub and v-belt pulley are made from die-cast aluminium, with reinforced ribs for prolonged lifetime

- Reduced stress on motor bearings

- Class A motor featuring excellent effi- ciency and low energy consumption

- Each motor is individually tested for 100% quality control

- Fan housing and venturi made of strong galvanised sheet-steel

- Welded wire guards designed for easy maintenance fitted with noise reduc- tion supports

- Propeller is statically and dynamically balanced

- Shutters are made of pressed gal- vanised steel in order to ensure high- est strength

- Shutter bearings are maintenance free

- Patented centrifugal system permits an energy efficient solution

- Dust-safe opening and closing

- Powerful springs keep shutters firmly closed when fan is not operating

- Every fan is individually checked for quality

Curves refer to data measured on EM50n by Bess Lab.

electric motor.

design.

Order Information

EM50n-X-X-X e.g., EM50n-b-2-wp-wm

- b : Code for electric motor according to above table.

- 2 : Code for the type of propeller blades.

- Galvanised propeller blades.

- Precoated propeller blades.

- Stainless steel propeller blades.

- wp-wm : Options codes

- wp: Fan equipped with plastic CE protection for belt and pulleys (on mesh side, standard in Europe)

- np: Fan delivered without plastic CE protection for belt and pulleys ( on mesh side, standard outside Europe)

- wm: Fan delivered with pyramidal shape mesh for CE protection on shutter side.

- nm: Fan delivered without pyramidal shape mesh for CE protection on shutter side (standard)

Motor Specifications

| EM50n Code | Nominal Power | Type phases |

Speed | Frequency[Hz] | Voltage[V] | Current[A] | rpm | ||

|---|---|---|---|---|---|---|---|---|---|

| [W] | [hp] | ||||||||

| a | 735 | 1 | 1 | single | 50 | 230 | 5 | 1,380 | |

| b | 735 | 1 | 1 | multi* | 50 | 230 | 5 | 1,380 | |

| c | 735 | 1 | 1 | single | 60 | 220-240 | 5.7 | 1,700 | |

| d | 735 | 1 | 3 | single | 50 | 230/400 | 3.5/2 | 1,400 | |

| e | 735 | 1 | 3 | single | 60 | 230/400 | 3.5/2 | 1,700 | |

| f | 880 | 1.2 | 3 | multi* | 50 | 230/400 | 4.3/2.5 | 1,380 | |

| g | 880 | 1.2 | 3 | multi* | 60 | 230/400 | 4.3/2.5 | 1,600 | |

| h | 1,100 | 1.5 | 1 | single | 50 | 230 | 7.3 | 1,400 | |

| i | 1,100 | 1.5 | 1 | single | 60 | 220-240 | 7.3 | 1,700 | |

| k | 1,100 | 1.5 | 3 | single | 50 | 230/400 | 5.2/3 | 1,400 | |

| l | 1,100 | 1.5 | 3 | multi* | 50 | 230/400 | 5.2/3 | 1,380 | |

| m | 1,100 | 1.5 | 3 | single | 60 | 230/400 | 5.2/3 | 1,700 | |

| n | 1,100 | 1.5 | 3 | multi* | 60 | 230/400 | 5.2/3 | 1,670 | |

* Multi speed motors must be regulated with auto-transformer which is not supplied.

Technical Specifications

| 1.0, 1.2 hp | 1.5 hp | ||

|---|---|---|---|

| Weight of fully equiped fan1 | [kg] | 84 | 86 |

| Nominal propeller speed | [rmp] | 368 | 427 |

| Airflow at 0 Pa1 | [m3/h] [cfm] | 36,180 [21,300] | 42,125 (24,800) |

| Airflow at 25 Pa1 | [m3/h] [cfm] | 31,594 (18,600) | 38,048 (22,400) |

| Airflow at 50 Pa1 | [m3/h] [cfm] | 25,139 [14,800] | 33,293 [19,600] |

| Specific performance at 0 Pa1 | [m3/wh] [cfm/w] | 34.5 [20.3] | 28.0 [16.5] |

| Propeller diameter | [mm] [inch] | 1,270 [50] | |

| Number of blades | 6 | ||

| Number of shutter blades | 10 | ||

| Max. operating temperature | [°C] [°F] | 50 [122] | |

| IEC protective class of electric motor | IP55 | ||

| Electric motor winding insulation grade | F | ||

1 All values refer to 3 phases 50 Hz single speed motor.

N.B Airflow data are measured at standard condition (20 °C, 1013 hPa).

EM 50n is developed and produced by Munters euroemme S.p.A., Italy.