Ideal for Air Circulation, Ventilation, Heat Distribution and Dehumidification.

Integrates with all other Environmental Control Systems.

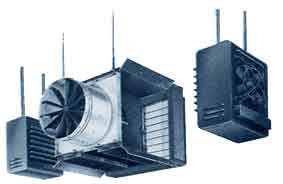

Fan-Jet air distribution system is one of the most diversified air moving products ever introduced to greenhouse, agricultural and product storage buildings.

It has industrial uses as well as hog, poultry and animal confinement uses.

The Acme Fan-Jet system integrates the movement of air for internal air circulation coupled with inducing fresh air into the building, removal of air through exhaust fans. It also dramatically increases air movement within the building. That is beneficial to growing crops, poultry, hog and animal health as well as providing much needed air circulation among product storage.

The Fan-Jet (or fanjet) can be used as greenhouse fans, agricultural fans, poultry fans, hog fans, ventilation fans or general cooling fans. It also works well in a fan and pad cooling system.

It also serves as a dehumidification system as well.

Fanjet systems design information can be found in the fanjet section of the Acme Climate Control Handbook

Overhead Heating System

The Need for Well-Distributed Heat

A greenhouse is a difficult structure to heat and it contains plants that are extremely sensitive to temperature variation. The greenhouse heating process is in itself unstable since the warmed air being lighter rises to the roof, while the cold air produced near the glass or plastic covering is heavier and tends to settle to the floor. Should this settling occur at any point, which it tends to do with still air in the house, a cold spot with extreme humidity’s may develop.

Overhead air motion and mixing will help prevent this settling action from the roof, but will only partially reduce the normal cold film of air flowing down the walls. This film of cold air is best handled by the release of heat from a perimeter heating system to intercept the cold air pouring down the walls before it gets to the floor. Also, in those areas where snow melting is required in gutter connected houses, provision should be made to supply gutter heat.

Since the temperature of the plants in a greenhouse is primarily determined by the inside air temperature, the main function of the heating system is to maintain a uniform air temperature in the house. The Fan-Jet systems both overhead and perimeter working directly with all the air in the greenhouse make an ideal method of heating the air and achieving this uniformity.

Description of a Fan-Jet Heating System

Use of a Heat Kit

The Fan-jet unit with a heating accessory “heat kit” is designed to receive the heated air from conventional type unit heaters, and in turn distribute this heated air uniformly throughout the house. The heating accessory consists of a baffle arrangement that closes the top and bottom space between the pressurizing fan and the inlet shutter. The sides remain open to admit the heated air blown from conventional horizontal discharge type unit heaters spaced a fixed distance away from the side inlets.

A center baffle accessory for the heat kit is included for use when opposing heaters are not operating simultaneously. The baffle prevents blow-through of heated air and possible heater motor, or heater combustion malfunction.

When the equipment control calls for heat and turns on the unit heaters, they blow heated air into the open sides of the Fan-jet which is propelled down the tube and distributed uniformly within the house. After the desired temperature is reached the unit heaters are automatically turned off while the Fan-jet continues running and recirculating the air within the house.

Since the heaters are not built into the main air flow path of the Fan-jet system, they never restrict the flow of air whether the system is supplying fresh air, heating, or recirculating air within the greenhouse. This results in much higher efficiency than other systems thus providing much more air flow for all its uses and at lower horsepower and operating costs. Moreover, steam or hot water type unit heaters may be used without any risk of freeze up.

When the Fan-Jet is used for ventilation, a motorized shutter opens, the Fan-Jet pulls air into the building and distributes it down the house through poly tubes designed for maximum air movement within the house. As the motorized shutter opens, an exhaust fan comes on that is balanced with the same CFM’s as the Fan-Jet, thereby exhausting the old air from the building and the Fan-jet brings in fresh outside air.

The Fan-Jet used as dehumidification.

When excess humidity is built up within the house, through evaporation of crop, watering plants in the greenhouses, and other ways humidity is added to the air, fresh outside air with lower humidity is introduced into the greenhouse, old air exhausted out of the house by exhaust fan and some dehumidification occurs.

In cases where there is high outside humidity, or further reduction of humidity is required, the air entering the house through the Fan-Jet is heated with a heater, mounted alongside the Fan-Jet. When air is heated 20 degrees, the humidity drops 50%. Therefore, this higher temperature air has a lower humidity and the Fan-Jet system spreads this lower humidity air throughout the house. Again, exhaust fan exhausts the high humidity air that is in the greenhouse.

The control of the system can be done with a humidistat for integrated controllers.

Fan-Jet for air circulation within a greenhouse.

This is a benefit to greenhouse crops, hog, poultry and animals, product storage and people.

For air circulation when a motorized louver is closed, the Fan-Jet fan distributes internal air through the house evenly and that air is then properly circulated, drawn back up through the Fan-Jet in a continuous airflow pattern that gives even flow of air within the house.

This system is also very beneficial in heat savings, as warm air rises and as the Fan-Jet is normally in the higher parts of the house, the circulation system forces the warm air down, down onto crops, people and product, thereby reducing heating costs.

Heat Kits for overhead heating

CAUTION! To avoid combustion malfunctions when two heaters are used with one Fan-Jet; the minimum heater distance from Fan-Jet opening must be maintained, both heaters must operate simultaneously unless center baffle is used, and the discharge louvers must be directed toward the top of the Fan-Jet opening.

Acme Heat Kits allow use of gas fired, electric, steam or hot water unit heaters without outside air passing through the heat exchanger. When used with Fan-Jet, Heat Kits keep coils and elements out of the air flow route, thus saving energy. Each kit consists of two baffle plates with air scoops attached horizontally to the top and bottom of the Fan-Jet Unit and to the framed opening of the motorized inlet shutter.

Kits also come with a Fan-Jet motor shield to prevent heat build-up. A center baffle accessory is included for use when opposing heaters trigger separately, preventing blow-through of hot air and possible motor damage.

“The unit heater louvers should be at the same elevation as the Fan-Jet inlet opening and spaced a proper distance from it, with the axis of the unit heater discharge opening directed toward the Fan-Jet inlet opening. If the heater must be positioned below the level of the Fan-Jet inlet opening to maintain the proper spacing, the louvers should be adjusted to direct the heated air upward toward the top of the inlet opening.

If the Fan-Jet end of the building is colder than the remainder of the house, this condition usually can be corrected by adjusting one or two of the lower louvers of the heaters to a downward position to divert part of the heated air to the end wall area.

CAUTION! Guards are strongly recommended when the fan is installed within seven (7) feet of the floor, working level or within reach of personnel. Guards complying with OSHA regulations are available as optional equipment. Review OSHA Codes and obtain a quotation.

Fan-Jet Characteristics

The unique Fan-Jet is a special tube pressurizing fan with curved stationary discharge vanes (stator vanes) that recover the rotational energy of discharging

air to increase performance capacity and efficiency.

LOW COST: Fan-Jet powers more air at less horsepower for best results at low operating costs.

QUALITY: Fan-Jet is fully assembled at factory, test run and inspected and then shipped ready to install with brackets and fasteners.

DIRECT DRIVE MODELS –

RC 18

Direct drive models are capable of variable speed control.

BELT DRIVE MODELS – RC 24, 30

Belt drive models features no-service sealed fan shaft ball bearings captured in a unique casting to maintain proper alignment and spacing.

BUILT TOUGH: The steel model RC is available in 18″, 24″ and 30″ sizes and is rust protected with a metal wash process and a two-coat, baked-on finish.

HIGH PERFORMANCE PROPELLERS: The propellers are matched to the size, performance and construction of the Fan-Jet. RC fan propellers are welded steel with a two coat finish.

ENERGY EFFICIENT: All motors are totally enclosed, high efficiency design with shielded ball bearings and include thermal overload protection on single phase models.

Models RC are listed by Canadian Standards ; Association Testing Laboratory as approved.

| FAN-JET PERFORMANCE DATA | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ‡Heating Capacity with Heat Kit BTU/Hr, Output Heater Temperature Rise of | ||||||||||

| Fan-Jet Model | HP | RPM | Tube Size |

System CFM |

Motorized Shutter Model |

Heat Accessory |

40º | 50º | 60º | 70º |

| †RC12D4 | 1/8 | 1725 | 12″ | 1180/780 | WAAC1818 | NA | NA | |||

| RC18E6 | 1/4 | 1160 | 18″ | 3120 | WAAC2626 | HT18 | 112,000 | 138,000 | 163,000 | 186,000 |

| RC/RCA24F | 1/3 | 735 | 24″ | 5420 | WAAC3333 | HT24 | 172,000 | 212,000 | 250,000 | 287,000 |

| RC/RCA24F2S | 1/3 | 735/490 | 24″ | 5420/2710 | WAAC3333 | HT24 | 172,000 | 212,000 | 250,000 | 287,000 |

| RC/RCA30G | 1/2 | 607 | 30″ | 8550 | WAAC4040 | HT30 | 278,000 | 342,000 | 403,000 | 463,000 |

| RC/RCA30J | 1 | 757 | 30″ | 10600 | WAAC4040 | HT30 | 345,000 | 424,000 | 500,000 | 574,000 |

Order Cam Motorizing kits for shutters separately.

‡ The Order rating for gas fired heaters is 80% of their input BTU ratings.

PLEASE ADVISE VOLTAGE REQUIREMENTS WHEN INQUIRING.