Modine Natural Gas Heaters,

Propane Heaters

THE MOST EFFICIENT UNIT HEATER IN NORTH AMERICA.

For International clients 1 KCal = 3.968 BTU

MODINE Effinity® Gas-Fired Unit Heaters

MODINE Effinity® Gas-Fired Unit Heaters

93% Efficiency Condensing

Operating at up to 97% thermal efficiency, Modine’s Effinity™ condensing unit heater features the highest efficiency available in North America for commercial and industrial gas-fired unit heaters, which will dramatically lower energy costs and CO2 emissions. This industry-leading efficiency is a result of the coupling of our secondary heat exchanger technology with our robust tubular primary heat exchanger design.

The Modine Effinity™ guards against mold and maintains uniform wall-to-wall temperatures with consistent air circulation.

All units are equipped with Building Management System (BMS) integration capabilities, allowing them to be added to existing BMS easily.

Features and Benefits

- Separated combustion – drawing combustion air from outside to ensure that the unit will always have plenty of fresh, clean air for combustion while increasing the overall heating efficiency.

- Helps promote a clean air growing environment — combustion fumes are vented outside, away from your plants.

- Fuel savings — up to 97% efficiency allows you to save otherwise wasted energy and money.

- Dependable and consistent performance accompanies Modine’s Concervicore Technology – providing power exhauster and dual heat exchangers.

- The secondary heat exchanger is made of AL29-4® stainless steel and comes with a 10-year warranty – eliminating corrosion concerns and extending the life of your investment.

- Building Management System integration capabilities allow these units to be added easily to any existing system.

- Energy Saver Controls – as the temperature increases, the gas is disabled, and stratified ceiling air is used to heat the space below. Once the ceiling air temperature decreases, the gas re-engages and heats the air.

- Contractor Convenience Package featuring a condensate pump convenience outlet, unit on/off switch, heater function status indicator lights, and external terminals for thermostat wiring.

- Just one Modine Effinity™ can lower CO2 output by thousands of pounds annually.

- Designed, Engineered & Assembled in the USA.

Savings are more than doubled compared to gravity-vented unit heaters.

With multiple units per building, it is not difficult to imagine the positive impact this can have on your bottom line and the environment.

Available models:

- Standard model PTC

- Blower model BTC

- Ten model sizes available – from 55,000 to 310,000 BTU/hr.

Options

- Upgrade to all stainless steel heat exchanger

- A selection of room thermostats

- Finger-proof fan guard

- Blowers available on models 215-310

Accessories

- Vent Cap

- Condensate pump

- Two-point suspension kit

- PH neutralizing kit

- Conversion kits for natural gas and propane, including high-altitude kits

- GFCI Surge protection adapter plug for service

- Concentric and Two-Pipe Vent Kits

- 30, 60 and 90 degree air deflector hoods

- Contractor Convenience Package featuring a condensate pump convenience outlet, unit on/off switch, heater function status indicator lights, and external terminals for thermostat wiring

For full list of accessories, please call 888-334-1440 or email usgr@usgr.com.

Hot Dawg®

MODINE GAS-FIRED UNIT HEATERS

SEPARATED COMBUSTION

The Hot Dawg® separated combustion garage heater pulls 100% of the combustion air from outside, making this unit ideal for workspaces such as wood shops or a garage where paint or flammable materials are used regularly. The fresh air supply reduces the common concerns about performance and durability that can come when working in a dusty or particulate-laden environment.

Certified for residential, commercial, and industrial use.

- In-shot burners fire each heat exchanger tube for reliable performance

- Same-size vent and combustion air inlets throughout product line

- Optional stainless steel heat exchanger

- Centrifugal blower models with adjustable sheaves for wide airflow range (BTS line)

- All products Made in the USA

Features and Benefits

- Draws combustion air from outside the workspace, ensuring the unit always has plenty of fresh, clean air to breathe.

- Reduces common concerns about dusty, dirty, or humid applications, providing more exceptional durability and reduced maintenance.

- The sealed compartment protects the combustion gas valve, ignition control, manifold, and burners from the environment.

- Factory assembled, certified separated combustion saves installation time.

- Low-profile, lightweight design easily installs 1″ from the ceiling with only two angle brackets*.

- Operates on natural or propane gas; field conversation kits are available.

- Finger-proof fan guards on all units.

- Reduces the need for maintenance with the permanently lubricated motor.

- 100% shut-off with continuous retry to allow for safe ignition in the event the unit doesn’t light on the first try.

- Right or left-hand controls are available on 30-75 BTU Models by rotating the unit 180 degrees.

- The power vented model simplifies side-wall or roof venting with the small-diameter vent pipe.

- Fuel Type: natural or propane gas.

- Designed, Engineered & Assembled in the USA

* Fuel Type: natural or propane gas, field conversation kits are available

MODINE GAS-FIRED UNIT HEATERS

MODINE GAS-FIRED UNIT HEATERS

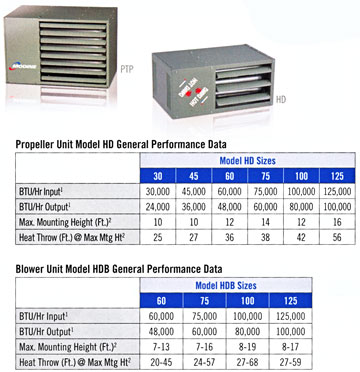

HORIZONTAL POWER VENTED

Ideal for greenhouse heating and air circulation, the power vented HD and PTP models are available in 13 different sizes to accommodate a full range of applications. Heaters can be equipped with natural or propane gas as well as automatic or manual operation. The all-new PTP unit heater line is made specifically with the greenhouse owner in mind. It includes all of the benefits found in the HD line, along with:

- Stainless steel heat exchanger comes STANDARD on all units to withstand corrosive combustion air found inside a greenhouse, extending the life of your investment

- 10-year heat exchanger warranty is STANDARD, providing you peace of mind

- Modine’s proven tubular heat exchanger design

- Optional finger-proof fan guard for low mounting height applications

BENEFITS OF HD AND PTP LINES INCLUDE:

- 80% thermal efficiency, maximizing seasonal efficiency for reliable performance

- Installs quickly and easily with field wiring connections and knockouts for quick access to gas and electricity

- Standard power exhaust simplifies side-wall or roof venting with small-diameter vent pipe

- Permanently-lubricated motor for trouble-free dependability

- Unit can be rotated 180 degrees, allowing for vertical or horizontal venting and easier access to controls (HD line)

- All products Made in the USA

MODINE GAS-FIRED UNIT HEATERS

MODINE GAS-FIRED UNIT HEATERS

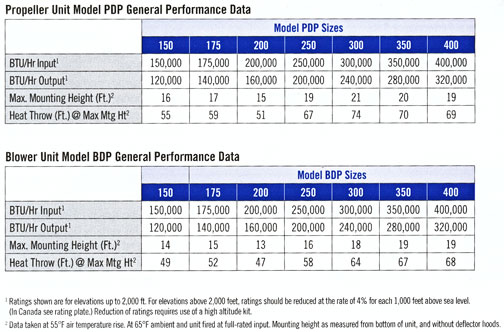

VERTICAL POWER VENTED

Modine’s PDP/BDP power vented unit heaters send all combustion products outside of the greenhouse, protecting sensitive plants from poisonous toxins. They are inexpensive to install, easy to use and offer excellent in-service economy. These units provide air circulation to reduce dead spots in the greenhouse, reducing high moisture areas that promote mold growth. Features include:

- 80% thermal efficiency, maximizing seasonal efficiency through the use of a collector box and the power exhauster

- A 100% shut-off, intermittent pilot-ignition system with continuous retry, at no extra charge. This ignition system allows for units to be field-converted to propane, if desired

- A power exhauster that can be rotated 180 degrees. The unit can be vented vertically or horizontally

- A safety pressure-switch to assure safe venting conditions

- Designed to utilize the smallest-diameter vent pipe possible

- A level hanging mechanism for easy field adjustments after adding accessories that may change the unit’s center of gravity

- Designed to operate against 0.5 inches of external static pressure

- All products Made in the USA

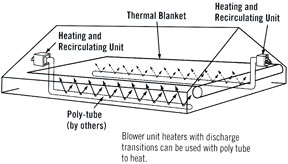

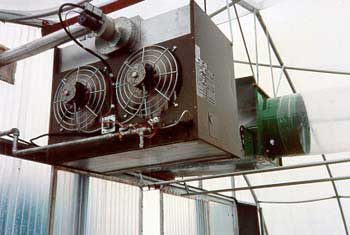

BLOWER EQUIPPED UNIT HEATERS

BLOWER EQUIPPED UNIT HEATERS

Blower units are designed for both heating and ventilating throughout the greenhouse. They may be used with poly tubes and turning elbows to economically heat overhead, or under thermal blankets or growing benches to save on fuel costs. Blower enclosures and filter racks are also available for ducting inlet air for CO2 enrichment.

Now, all gas-fired unit heaters can be equipped with blowers, including the Effinity93. In fact, the Effinity93 is the only high efficiency gas-fired unit heater in North America with this option available.

ACME / Modine Fan-Jet Air Delivery Heating,

Air Moving And Ventilation System

- For those will propane, natural gas, steam / hot water and in some cases the fan-jet in combination with air delivery heaters is an in expensive, efficient, quick, dominant way to heat many kinds of structures.

- Greenhouses, packing areas, warehouses, dairy barns, hog / poultry operations, Many different applications, We recently completed a potatoes storage facility to reduce mildew, and in crease air movement.

MODINE GAS-FIRED UNIT HEATERS

MODINE GAS-FIRED UNIT HEATERS MODINE GAS-FIRED UNIT HEATERS

MODINE GAS-FIRED UNIT HEATERS

BLOWER EQUIPPED UNIT HEATERS

BLOWER EQUIPPED UNIT HEATERS