Plant Growth /

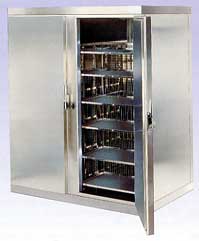

Germination Cabinets

Plant growth and germination cabinets are based on the cooled incubators detailed below. Day and night conditions are automatically simulated and can be easily programmed.

Temperature Control

Temperature Control

All plant growth cabinets use the same temperature control systems as the cooled incubators on which they are based. Temperature performance can be marginally affected during the “lights on” cycle due to a small amount of heat from the lights radiating into the growth chamber. The temperature is cycled using a 24 hour timer.

Illumination

All models are fitted with a digital 24 hour timer to control the day/night cycle of lights on and off. Each incubator door is fitted with one pair of white fluorescent tubes. These give a lighting intensity of approximately 3000 lux on each shelf. For higher lighting intensities and specialised applications, extra lights or UV lamps can be added. All lights are mounted in the outer door which is vented at the top and bottom. This means that the unwanted heat can escape into the laboratory. Cabinets fitted with four or more lights in each door also have a small extract fan in the door to help remove heat. This helps to maintain stable control, especially at lower operating temperatures.

High Humidity Models

Two models (SL2 & SL3) are sealed chamber versions of models PL2 and PL3 respectively and should be used for high humidity applications.

Optional Extras

- Chart recorder.

- Audible alarm.

- Humidity control.

- Remote alarm contacts.

- Additional light available by quotation.

| Models | PL2 & SL2 | PL3 & SL3 | PL33 | LT601L | LT1201L |

|

Temperature* Range (lights off) Range (lights on) Control (lights off) Variation (lights off) Refrigerant

|

0°C to +60°C +5° C to + 60°C Typically ±0.2°C* Typically ±0.5°C* R12 or CFC -free

|

0°C to +50°C +5° C to + 50°C Typically ±0.2°C* Typically ±0.5°C* R134a |

|||

| Timers for Cycling |

Digital 24 hour as standard,

(7 day alternative if specified) |

||||

|

Construction Chamber Exterior Castors Access Port Insulation

|

Stainless steel White painted steel Optional Standard, 2 x 12mm CFC-free |

Stainless steel Stainless steel Standard, lockable Standard, 12mm Foamed in place |

|||

| Chamber Capacity (litres) | 150 | 320 | 730 | 600 | 1275 |

| Dimensons (mm) External H | 1075 | 1745 | 1745 | 1980 | 1980 |

| W | 635 | 635 | 1270 | 710 | 1420 |

| D | 660 | 660 | 660 | 800 | 800 |

| Max. Internal H | 590 | 1275 | 1275 | 1480 | 1480 |

| W | 510 | 510 | 1140 | 590 | 1300 |

| D | 490 | 490 | 490 | 650 | 650 |

| Shelves Supplied | 4 | 6 | 6 | 5 | 10 |

| Weight (kg) | 100 | 145 | 250 | 125 | 190 |

| Power Rating (W) | 900 | 900 | 1250 | 900 | 1700 |

* Temperature specification for Models PL2 & SL2 at 20°C ambient.

Custom Built Rooms

Rooms will meet very high performance criteria at a competitive price. Temperature stability performance of better than ±1 °C and a humidity control of ±3% are typical.

Alarm and monitoring of the room parameters can be conveniently achieved using the LAM100 system

A NAMAS traceable calibration certificate is available with every temperature controlled room.

Construction

All rooms are constructed from interlocking insulated panels incorporating polyurethane foam insulation of between 60mm and 100mm thickness, dependant on the specification requirements. These panels meet or exceed European specifications for `fire retardation’ and `surface spread of flames’.

Floors are normally insulated and given a nonslip finish for safety. Specialist finishes are also available. Some applications can be specified without an insulated floor.

Internal and external wall surfaces are usually of corrosion resistant steel finished in a food safe plastic laminate. Stainless steel is recommended when the room is to be humidified or possibly exposed to potentially corrosive vapours.

Hinged doors have an external lock and an internal safety release mechanism. Sliding doors can also be fitted to larger rooms.

Temperature Control

Rooms with operating control from -20°C to above +40°C have all been successfully installed. Incubator rooms typically have temperature control to better than 1°C.

Microprocessor controllers automatically call for heating or cooling only as required, in order to achieve optimum temperature stability with maximum operating efficiency. (This is in marked contrast to other systems which constantly overcool and then have to add excessive heating power in order to achieve the required temperature).

For cooled incubator and refrigerator applications direct cooling is usually specified. Indirect cooling, where chilled water is circulated through a heat exchanger, is often the method of choice in humidified rooms. An over temperature safety thermostat is always fitted as standard.

Humidity Control

Lighting Control

Rooms for use in seed germination and plant propagation will require specialised shelving and lighting control. Overhead lights are automatically switched on and off at predetermined times in order to simulate day and night conditions. Rooms for this application will always have cooling and dual temperature cycling as standard.

Shelving

An extensive range of shelving is available for use in these rooms. Shelving can be made from stainless steel, aluminium, chrome plated wire, etc. dependant on user requirements.

Additionally, a wide selection of internal fittings can be supplied, including standard benching, sinks and fume extract units. Alternatively, The rooms can be supplied empty to take the customer’s own fixtures and fittings.

Optional Extras

- Chart recorder.

- Panic alarms.

- Alarm monitoring see pages 10 to 11.

- Various types of racking and shelves.

Humidity Cabinets: Ultrasonic Control

Humidity Cabinets: Ultrasonic Control

This comprehensive range of humidity cabinets includes both active RH control and saturated salt models.

Construction

All cabinets have stainless steel interiors fitted with adjustable shelves. All SF models have sealed chambers making them suitable for humidities up to 98%. LT models do not have sealed chambers and their use is restricted to a narrower range of humidity control. SF models can have an outer door heater to demist the inner toughened glass viewing door. CFC-free polyurethane insulation provides very efficient thermal stability in all models. Two 12mm access ports are provided as standard.

Specification – Ultrasonic Control Types

| Models |

SFC2C/RH | SFC3C/RH

Directly Cooled

|

LT601/RH | LT1201/RH

Directly Cooled |

||

|

Temperature Range Control Variation

|

+5°C to +50°C ±0.5°C at +20°C ±0.5°C at +20°C |

+5°C to +50°C ±0.5°C at +20°C ±0.5°C at +20°C |

||

|

Humidity Range Control

|

30% to 98% RH | 40% to 95% RH | ||

|

Typically ±30%

RH at +20°C operating temperature |

||||

| Dimensons (Max. mm)External H | 1075 | 1745 | 1980 | 1980 |

| W | 635 | 635 | 710 | 1420 |

| D | 660 | 660 | 950 | 800 |

|

Internal H |

590 | 1275 | 1480 | 1480 |

| W | 510 | 510 | 590 | 1300 |

| D | 490 | 490 | 650 | 650 |

| Chamber Capacity (L) | 150 | 320 | 600 | 1275 |

| Shelves Supplied | 4 | 6 | 5 | 10 |

| Weight (kg) | 100 | 145 | 125 | 190 |

| Power Rating (W) | 800 | 850 | 600 | 1275 |

* Temperatures down to +10°C using optional extra cooling unit.

** Temperatures specification at 20°C ambient.

Humidity Cabinets: Salt Solution

Temperature Control

Monitoring and control of both heating and cooling functions is performed with great accuracy, and achieves typical temperature stability of ±0.5°C. The LED digital display allows the temperature performance to be easily verified. A digitally set over temperature safety cutout is fitted to all models.

Humidity Control (Ultrasonic Type)

All /RH models are fitted with an ultrasonic fine mist humidity generator located in the airflow. The microprocessor controller accurately monitors and adjusts the chamber humidity level. All RH models are able to dehumidify as well as increase humidity.

It should be noted that not all combinations of humidity and temperature are possible. Temperature and humidity performance varies according to the combination selected. Please contact us for advice on which model will best meet your requirements.

Typical Operating Range – for Model SFC3C/RH with ultrasonic humidifier

Humidity Control (Salt Solution Type)

Salts-type SF models rely on forced evaporation from trays containing known saturated salt solutions. This is a simple and reliable method of humidity control.

Specification – Ultrasonic Control Types

| Models |

SFC2

|

SFC3 | SFC3C | SFC30 |

| Directly Cooled | ||||

|

Temperature Range** Control Variation

|

Ambient +5°C to +60°C ±0.2°C at +37°C ±0.5°C at +37°C |

+5°C to +60°C ±0.2°C at +20°C ±0.5°C at +20°C |

||

|

Humidity Range Control

|

0% to 98% using appropriate

saturated salt solution |

|||

| Dimensons (Max. mm)External H | 880 | 1550 | 1075 | 1745 |

| W | 635 | 635 | 635 | 635 |

| D | 660 | 660 | 660 | 660 |

|

Internal H |

590 | 1275 | 590 | 1275 |

| W | 510 | 510 | 510 | 510 |

| D | 490 | 490 | 490 | 490 |

| Chamber Capacity (L) | 150 | 320 | 150 | 320 |

| Shelves Supplied | 4 | 6 | 4 | 6 |

| Weight (kg) | 75 | 120 | 100 | 145 |

| Power Rating (W) | 200 | 250 | 800 | 850 |

* Temperatures down to +10°C using optional extra cooling unit.

** Temperatures specification at 20°C ambient.

CIF Europe 6-8 weeks dilivery

Prices begin at $0 to $0 and ups

Temperature Control

Temperature Control Humidity Cabinets: Ultrasonic Control

Humidity Cabinets: Ultrasonic Control