SOIL AND MEDIA BAGGING- -SOIL AND MEDIA HANDLING

Soil bagging for self use or resale generally requires development of soil bagging and soil handling equipment.

Bagging and handling equipment is used to bag and process more than just soil. It is also used to mix and bag various soil components and many other materials that need to be mixed and bagged. We custom make equipment to fit our client’s needs based upon material to be bagged and possibly mixed. The size of bags and number of bags to be bagged in a given number of time, hourly, daily, seasonally, helps determine which bagging operation is best for you. The weight consistency and moisture content of the material is also reflected in the type of bagging equipment required.

When bagging materials, conveyors are required to conduct the material to the soil bagger and other conveyors generally to remove the material after it has been bagged in larger operations. In smaller operations, the soil or other media or materials can be semi-automatic or even manual. After the product is bagged, it has to be sealed. We have excellent sealers, and often bag kickers to flip the bag to prepare for shaping the bag for easier stacking, reduced storage and more compact shipping.

Whether you are bagging soil or mixed media or other materials, we can provide you with the technology and equipment economical, efficient and manual, semi-automatic and completely automatic soil and media handling equipment.

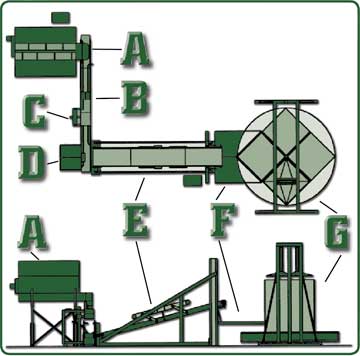

This is an example of soil bagging, using our most popular soil bagger, as well as the optional bagging equipment. However we have larger and smaller baggers and optional equipment is available in different sizes and different equipment depending upon your particular need. Many of our bagging projects are custom size to meet a wide variety of needs. Shown here is typical.

Soil Baggers

Volumetric Soil Bagger

The operator simply places a bag around the quick-clamp bag chute and steps on the foot pedal to open the bag and fill it with soil. A digital display allows for various bag sizes to be stored in memory for easy recall and repeatability. Bags can be sealed with a manual wire tie or optional automatic hot air sealer/ trimmer.

| SPECIFICATIONS | FEATURES |

|---|---|

| 4 yd Soil Hopper | Production Rate Examples: |

| 230 VAC, Single or Three Phase | 8 quart=18-20 bags per minute |

| 6 CFM Required | 3 cubic feet= 12 bags per minute |

Model No: 170

U.S. manufactured,

shipped from U.S. factories

and warehouses

The Soil Bagger is a bagging machine that can accurately bag tough, dense soils, as well as lighter potting mixes. It will handle most grades of potting soil with accuracy and speed. The Soil Bagger uses a foot switch, leaving the operator’s hands free.

The automatic bag holding chute opens, holding the bag tightly while covering the mouth of the bag, which eliminates excessive dust while filling. When filling is complete, the chute closes and releases the bag. Quick change-overs are handled with PLC controls and a pin-connected bag chute. Easy to operate and low maintenance make this a must-have machine for any soil bagging operation.

The Soil Bagger will fill bags from 8 quarts to 3 cubic feet. System includes a 4 cubic yard material hopper, lengthwise and crosswise agitators, 5HP hydraulic power unit, variable speed, and PLC controls.

Specs:

| Power: | Hydraulic 5HP/ 220V/ single or three phase/ 50 or 60 Hz |

| Dimensions: | 102″L x 75″W x 116″H |

| Production: | Up to 18 bags per minute |

| Weight: | Approximately 1,400 lbs |

| Options: | Bag carrying conveyor Hot Air Sealer Bag Kicker Bag Flattening Conveyor Elevating Platform Palletizing Carousel |

| Portability: | Stationary |

Optional Bagging Accessories

The bags then travel to the bag kicker (D) and are diverted onto a bag flattening conveyor (E), where they are compressed and flattened while moving up the elevating platform (F). Bags are then stacked on the palletizing carousel (G).

The elevating platform is raised hydraulically as the stack on the carousel becomes higher. When the pallet is filled, the platform can be lowered and the carousel then rotated 90° to provide personnel with a new pallet. The filled pallet is then taken away by a forklift and is ready to be stretch-wrapped for shipment.

Diagram key:

A – Soil bagger

B – Bag carrying conveyor

C – Hot air sealer

D – Bag Kicker

E – Bag flattening conveyor

F – Elevating platform

Other

We also have sub-contractors that provide special shrink wrapping based upon size and quantity and volume of product.

MANY OF OUR CLIENTS IN THE LANDSCAPING AND MEDIA SOIL/MEDIA HANDLING AND PROCESSORS ALSO REQUIRE CONVEYING LOOSE OR MIXED MEDIA OF VARIOUS TYPES OVER SHORT AND LONG DISTANCES. THEREFORE WE DIRECT YOUR ATTENTION TO OUR EXCEPTIONAL LINE OF CONVEYORS THAT ARE DESIGNED TO CONVEY, NOT ONLY SOIL AND MEDIA BUT ALSO WE CAN PROVIDE CUSTOM MATERIAL AND HANDLING FOR:

|

|

Leasing option available.

Also see: