GREENHOUSE POLYCARBONATE COVERINGS,

POLYCARBONATE CONVERINGS FOR

INDUSTRIAL AND COMMERCIAL USES

Polycarbonate is an outstanding

replacement product for glass and

poly covered greenhouses.

Retrofit assistance provided.

Used in sports arenas, greenhouses,

hurricane shutters, bus shelters, car ports, sunrooms, covered walkways, partition walls, facades, and roofing.

Specifications of Style

USGR offers polycarbonate coverings for all types of applications such as greenhouse, institutions, research facilities and retail greenhouses. Our 8mm Polymatte™ sheets provide 77%light transmission and 100%light diffusion which create optimal light conditions for enhanced plant growth.

We have supplied polycarbonates from factories around the world to cleats in all industries – and in quantity from small units to many thousands of square feet. Greenhouse is a major user of the product but other recent contracts have been:

- High impact product for train locomotive windows

- Skylights for resort and industrial uses

- Large aquarium installation

- Large patio covering

- Walkways

- Sheet material for diverse uses

- Insulating and lining panels

- Greenhouse polycarbonate covers

- Nurseries

- Hobby Greenhouses

- Commercial Greenhouses

- Institutional Research Greenhouses

- Agricultural and Low-Tech Greenhouses

- Aquaculture Facilities

- Biomass Growing Houses

Applying twin wall to roof of structure

SO CLEAR, SO TOUGH AND WEATHERABLE,

IT LEAVES POLY IN THE SHADE

THE MOST POPULAR GREENHOUSE POLYCARBONATE PANEL BUT USED

WORLDWIDE FOR MANY PURPOSES BESIDES GREENHOUSES

These Polycarbonate panels offer the design flexibility, easy installation and economy without premature surface deterioration or loss of light transmission. Polymatte, Twin Wall, Multi Wall and Corrugated polycarbonate sheet fills an important cost/performance niche in rigid coverings. With service life years longer than polyethylene or fiberglass wall, and more economical than glass.

Check These Outstanding Features:

- Excellent insulation

- Controlled daylight transmission

- Virtually unbreakable

- Flexible and easy to install

- Flame retardant

- Lightweight

- UV-blocking

- Environmentally friendly

- Available in polished and matte clear, as well as tints.

- Made in U.S.A.

- For high light greenhouse use

- Special greenhouse panels for light transmission.

Impact Strength

Our multi wall sheets are constructed from multiple layers of polycarbonate for maximum strength, with an internal cellular structure that makes them light and flexible.

Please see our corrugated polycarbonate sheets specifications page for technical details.

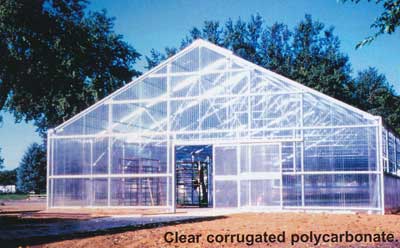

Typical Corrugated Installation

Note width of corrugation. Example shown is Greca configuration which is modified corrugation and

definitely the most popular.

COMMECIAL, INDUSTRIAL

AND AGRICULTURAL APPLICATIONS

Twin wall Polycarbonate Triple

Wall is available.

Excellent uses and cost effective applications for:

- Greenhouses

- Skylights

- Covered walkways

- Sun rooms

- Canopies

- Retail outlets

- Industrial applications

- Greenhouses/Nurseries

Contact us for various designs and options.

Please see our multiwall polycarbonate sheets specifications page for technical details.

It is always best to put permanent material in ends of houses because

It is extremely difficult to form poly around equipment.

Also great For sidewalls on Quonsetter, Quality Plus, Ventsetter, etc.

where you Have a 4 ft plus wall.

LEXAN DRIPGARD

LEXAN® DRIPGARD® material is a double walled extruded polycarbonate sheet offering thermal insulation, impact strength, high light transmission, long-term weatherability and lightweight – plus

added resistance to condensate build-up.

LEXAN® DRIPGARD® sheet is backed by a ten-year warranty against discoloration and loss of light transmission and a five-year warranty against hail damage. (Warranty specifications available upon request.)

- Standard Anti-Condensate feature

- 71-1/4″ wide sheets provide 6′ coverage

- .266 lbs. per square foot for 6 mm

- .35 lbs. per square foot for 8 mm

- Lengths cut to size up to 48′ long.

- Available in white, bronze, and smoked grey, for an additional charge. Please contact us for more details

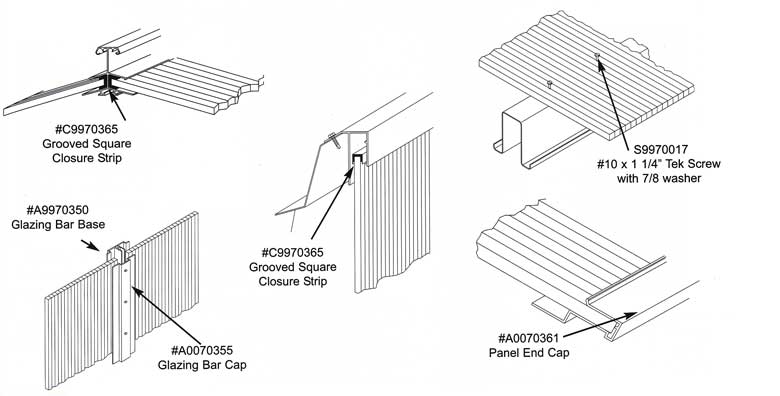

Typical Twin Wall Extrusions and Accessories

| FASTENING ACCESSORIES | ||

|---|---|---|

| DESCRIPTION | USED FOR | ORDER # |

| #10-16 x 3/4″ Tek Screw w/ Double Washer | corrugated to steel | S9970055 |

| 410-16 x 1-1/4″ Tek Screw w/ Double Washer | corrugated to wood | S9970013 |

| 410-16 x 1-1/4″ Tek Screw w/ 7/8″ Washer | twinwall | S9970017 |

| 410-16 x3/4″ Tek Screw w/ 7/8″ Washer | w/ lap fastener | S9970014 |

| 410 x 3/4′ Tek Screw , w/o Washer | w/ A9970350 | S9970010 |

| Aluminum Nails #10 x 1-1/4″ w/ Washer | wood frame | N9970020 |

| Sq. Closure Strip for Twinwall Polycarbonate. | vertical areas | C9970355 |

| Grooved Sq. Closure Strip for Twinwall Polycarbonate. | horizontal areas | C9970365 |

| Twinwall Glazing Bar Base 24′ Long (6 lbs.) | w/ S9970010 | A9970350 |

| Twinwall Glazing Bar Cap 24′ Long (3.9 lbs.) | w/ S9970043 | A0070355 |

| Screw Type “A” #10 x 12″, w/o Washer | w/ A9970355 | S9970043 |

| Twinwall Panel End Cap 12′ Long (3.5 lbs.) | w/ S9970010 | A0070361 |

| Tape for top of sheet 1″ Wide x 150′ Long | Top | T9970010 |

| Tape for bottom of sheet 1″ Wide x 150′ Long | Bottom | T9970020 |

| Spacer (4 per girt run in 6′ width) – with adhesive back | w/ S9970017 | W9970300 |

Installing Twin wall Polycarbonate on Your Greenhouse.

Taking care of some simple techniques will make your projects successful.

- Always install the sheets with the flutes oriented vertically. When

used as a roof covering, design with at least a 5 degree slope, never

horizontal. - Remember to allow for expansion and contraction in every installation.

Bronze and Gray panels change more in size. Use extrusions that allow

for sufficient edge engagement plus the expansion allowance. - Panels can be cut with protective masking in place with a fine tooth

saw or a sharp knife. Remember to remove the masking prior to final

fixing in place. Chips from cutting should be blown out of the flutes. - The specially treated weather side is identified on the masking. This

side must always face the exterior. - In vertical installations, the top flutes should be capped with an

extrusion or tape and the bottom left open for drainage. Vented tape

can be used on the bottom.

Storage of Panels

The sheets should be stacked on a solid flat surface. Store out of direct

sun to avoid accumulated heat effects. Cover for protection. Never use flexible

vinyl sheets as a cover as the plasticizes may react with the Polycarbonate.

Chemical Resistance

The following are considered safe:

- Acetic Acid

- Antimony Chloride

- Butane

- Calcium Hypochloride

- Carbon Monoxide

- Copper Sulphate

- Ethylene Glycol

- Hydrochloric Acid – 20 %

- Hydrofluoric Acid – 5%

- Oxygen

- Sulphur

- Water

- Ammonium Chloride

- Borax in Water

- Calcium Chloride

- Carbon Dioxide

- Citric Acid – 10%

- Ethyl Alcohol – 95%

- Formalin – 10%]

- Methane

- Mercury

- Ozone

- Urea

The following require caution:

- Cyclohexane

- Formic Acid

- Heating Fuel

- Perchloric Acid – Conce

- Sulphur Dioxide

- Diesel Oil

- Glycerine

- Jet Fuel

- Gasoline

- Turpentine

The following will attack Polycarbonate:

- Acetone

- Ammonia

- Benzene

- Buty Acetate

- Dimethly Formamide

- Hydrochloric Acid-Conc

- Hydorfluoric Acid-Conc

- Methyl Ethyl Ketone

- Perchloroethylene

- Toluol

- Sulphuric Acid – Conc.

- Acrylonitrile

- Amyl Acetate

- Bromine

- Chloroform

- Caustic Soda

- Ether

- Iodine

- Methanol

- Styrene

- Xylene

Attaching materials are for all conditions.

Special attachments required for greenhouse and nursery.

Important ordering information:

- Standard maximum length: 24 ft.

- Special orders up to 39 ft 6 inches available — 90 days delivery. High minimum order for unusual applications; generally not recommended.

- Sinus, Arch and Wave configurations popular in international market High minimum orders. 90 day delivery.

- Minimum of 6 panels per length.

- Minimum order 400 square feet or $500, whichever is

greater. - Skid charges depend upon length and width of panels; minimum $500.