Poly-Pipe Irrigation

FIELD POLY PIPE IRRIGATION

FOR TYPICAL LEVEL GRADE FARMING

Polyflex pipe fittings and tubing, a leading manufacturer of agricultural and horticultural plastics, uses only the finest polyethylene material which is more flexible than PVC.

We use the latest technology to ensures Poly-Pipe’s performance against the elements, especially the sun’s harsh ultraviolet rays.

Along with this strong commitment to quality, Poly- pipe gives the most cost effective irrigation system available next to, of course, Mother Nature.

How Polyflex Poly-Pipe brings your irrigation costs down.

- Eliminates costly main ditch cutting for irrigation and the need for dams on small grade changes.

- Can eliminates labor intensive hand priming of siphon pipe systems.

- 24 hour vigils searching for breaks in water soaked banks is not necessary.

- Reduces water costs by ending loss through evaporation or percolation.

- Increases productivity by allowing you to irrigate where you want, when you want.

- Less friction allows water to travel farther without boost.

- With careful installation, retrieval and storage, you can use Poly Pipe for several seasons.

- Durable polyethylene material is chemically more stable than PVC and stands the test of time

Dry headlands permit easy access to all gates for precise adjustments and fittings and optimum control over water flow and irrigation.

USGR’s Poly-Pipe flexible field pipe is primarily designed for use with typically level grade farming. Please take note that Poly-Pipe will not transfer water over hills or upgrades / up hills. Most standard headlands are level or have a slight or small downgrade and are perfect for Poly-Pipe. Minimum Order is 8 Rolls/1 pallet.

| Diameter | PRODUCT DESCRIPTION | ||||

|---|---|---|---|---|---|

| Thickness | LAYFLAT | LENGTH | |||

| 5 | 6 mil | 8 inches | 500 feet | ||

| 7 | 7 mil | 11 inches | 1320 feet | ||

| 7 | 10 mil | 11 inches | 1320 feet | ||

| 9 | 7 mil | 14 inches | 1320 feet | ||

| 9 | 10 mil | 14 inches | 1320 feet | ||

| 10 | 7 mil | 16 inches | 1320 feet | ||

| 10 | 9 mil | 16 inches | 1320 feet | ||

| 10 | 10 mil | 16 inches | 1320 feet | ||

| 10 | 15 mil | 16 inches | 660 feet | ||

| 12 | 7 mil | 19 inches | 1320 feet | ||

| 12 | 9 mil | 19 inches | 1320 feet | ||

| 12 | 10 mil | 19 inches | 1320 feet | ||

| 12 | 15 mil | 19 inches | 660 feet | ||

| 15 | 7 mil | 23.5 inches | 1320 feet | ||

| 15 | 9 mil | 23.5 inches | 1320 feet | ||

| 15 | 10 mil | 23.5 inches | 1320 feet | ||

| 15 | 15 mil | 23.5 inches | 660 feet | ||

| 18 | 9 mil | 28.25 inches | 1320 feet | ||

| 18 | 10 mil | 28.25 inches | 1320 feet | ||

| 18 | 15 mil | 28.25 inches | 660 feet | ||

| 20 | 9 mil | 31.5 inches | 1320 feet | ||

| 20 | 10 mil | 31.5 inches | 1320 feet | ||

| 20 | 15 mil | 31.5 inches | 660 feet | ||

| 21 | 10 mil | 33 inches | 1320 feet | ||

| 22 | 10 mil | 34.5 inches | 1320 feet | ||

| 24 | 10 mil | 37.5 inches | 1320 feet | ||

Other sizes available. Please call +1 (888) 334-1440 or email usgr@usgr.com

For Pricing information, please give Diameter, Thickness (mil), Length of each roll if not standard and number of rolls. The minimum order is 8 rolls in certain cases/1 pallet.

Gates supplied on request. Please state total number required.

Installation Instructions

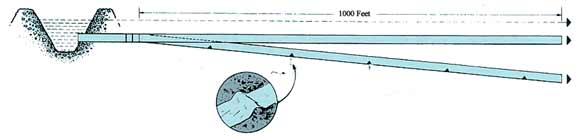

The POLY-PIPE is primarily designed for use with level grade farming. It will not transfer water over hills or up grades. Most standard headlands are level or have a slight downgrade and are perfect for POLY-PIPE.

Restrictions for sloped headland (more than 2 to 3 ft per 1000 drop or rise).

Headlands with downgrades of more than 2-3 feet per 1000 feet may need intermittent restriction in the POLY-PIPE line to assure even water flow to the crop rows.

Be sure you have sufficient waterhead (Level or Slight Grades)

Head is the WATER SURFACE HEIGHT ABOVE GROUND LEVEL. At least 6 inches of head is required for water to enter smoothly into the tubing and transfer across level or slight downgrade headlands.

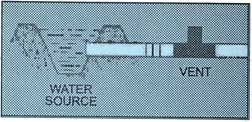

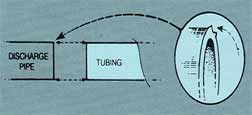

Pressure relief vents

The use of an open-topped air vent is advised at the connection point of the tubing. Vent allows excess trapped air to escape, thus, avoiding burst damage in the tubing. On long tube runs. pressure relief vents are required to avoid damage to your tube.

Pump water source

Most irrigation tube installations should include placement of an air vent 10 feet from the discharge pipe as well as on high spots

Operation

Begin with a small water flow and gradually increase to a full rate. As the POLY-PIPE tubing is filling (starting from the intake end of the tubing) punch gate holes or install adjustable gates as required. Consult your local dealer or county agent for recommended flow rates for your soil type and conditions.

The gate holes or adjustable gates should be installed between the 2 and 3 O’clock position.

NOTE : These instructions are general and act only as a guide for installation. Due to environmental and field condition variance, some steps may not apply to your particular operation.

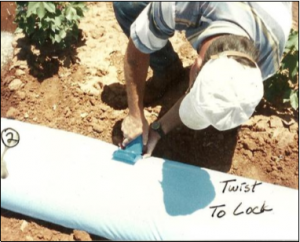

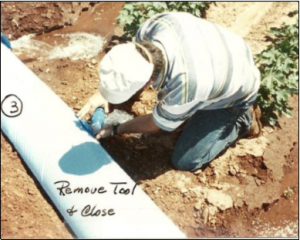

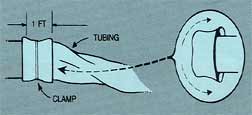

Connection Instructions

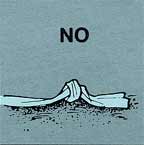

The diameter of the discharge pipe must correspond or be smaller than the

POLY-PIPE that is to be attached. Rough or sharp edges should be smoothed

or taped before the connection.

Cuff approximately 1 foot of POLY-PIPE no to itself to form a double thickness

over the pipeline. Secure with a hose clamp.

Make sure the connection is at ground level or supported with dirt so the

POLY-PIPE does not hang off the connection. Slack should be left at the

water source to keep the tubing from pulling off the connection.

Tube Laying Instructions

To ease the initial strain on the discharge connection, have someone hold

the tubing until the pulling tension is no longer there.

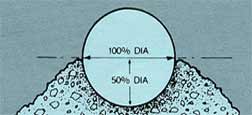

POLY-PIPE must be laid evenly in a continuous trench, 50% of the tubing

diameter in depth and 100% of the diameter in width. The trench prevents

the POLY-PIPE from rolling when filled with water.

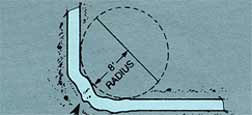

POLY-PIPE is flexible enough to complete a 90 degree turn with a 6 to 8

foot radius. Be sure trench radius is even on all corners.

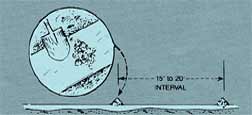

A shovel of dirt every 15 to 20 feet will keep the tubing in place during

installation as well as maintaining proper tension for smooth unrolling

of the tubing

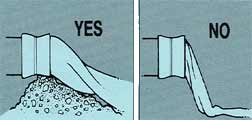

For irrigation, the open discharge end of the POLY-PIPE tubing should be

placed over a berm approximately 3 feet in height. This will prevent a

buildup of excess pressure in the tubing and avoid damage to the system.

The eventual pressure buildup will burst the tubing.

J. VENTING

Improper venting is the most frequent cause of problems. If air builds up in the pipe it will restrict water flow and drive up pressure. An open top vent located about 10 feet away from the water source is best. Additional vents will be required at high spots. These are usually just gates punched into the top of the tubing.