Seed Processing Equipment

STS-MC3 Mobile Cabinet Seed Separator

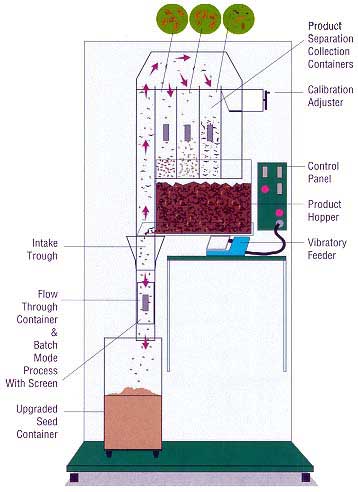

A breakthrough in cleaning and upgrading ! A machine that literally pays for itself by being so sensitive in calibration that it can separate seed based on moisture and tissue development of the seeds density, and thus dramatically improves seed germination. The STS-MC3 Air Separator uses a dual pressurized vacuum method to provide high efficiency cleaning and precise upgrade separations. Its mobile cabinet feature provides a portable & locking caster wheel operation. In addition, the STS-MC3 Air separator provides a dual vacuum system (dual switch) built-in the mobile cabinet for a quieter operation when in use. Whatever air velocity the operator chooses when seed enters the feed chute, the light, split, and other debris are lifted by air flow up through the column and are separated into 2 or 3 batching compartments. Seed separation was never so easy!

Seed Separator Features

- Built-in dual vacuum operation

- Portable and locking wheel control panel and cabinet

- Two modes of operation: Permanent continuous feed or small lot batch separation

- Virtually hands free operation

- Responsive air and product control

- Total visibility of all product movement

- Safety flow relay switch prevents seed contamination

- User friendly

- Calibration is fast and simple

- No mechanical maintenance required

- Environmentally clean

- Fits into small areas

Seed Separator Uses

- General Cleaning: The STS-MC3 can be used to clean seed by removing large particle/granular debris, chaff, inert material, pieces of broken seeds and other light unwanted materials.

- Close Grading: The STS-MC3 can be used to “grade” seed based on density or volume weight (e.g., removal of light seed or insect damaged seed.)

- Precision Upgrading: Detailed upgrading based upon a stratified, vacuum pressurized, calibrated air stream. The STS-MC3 will separate partially filled and immature seeds and improve the quality of the lot and therefore, enhance seed lot viability an germination.

Proven Seed Separation

The STS-MC3 separator has been proven to be highly effective in upgrading product and has accomplished what other processing machines do collectively

using only a single-step process.

. The STS-MC3 has been proven to recover seed losses from other processing machines. As much as 25-50% more seed yield was gained from the recovery with the same or higher germination.

Seed Separator Specifications

| STS-MC3 | (Approx.) |

|---|---|

| Overall Dimensions: | height: 84″ width: 48″ depth: 48″ |

| Vibrator Feeder: | 220v, 1ph, 50/60 Hz |

| Wall Controller: | 220v, 1ph, 50/60 Hz |

| Automatic Vacuum Controller: | 220v, 1ph, 50/60 Hz |

| Total System: | 12 AMPS |

| Dual Vacuum Control Seeds per lb. Capacity |

25-100 lb/hr. (depending on product density) |

Seed Separator Options:

- 115 V., 1 ph, 60 Hz

- 230 V., 3ph, 50/60 Hz

These specifications are general and are subject to change without notice.

STS-MC3 Precision Separator

- (1/230V, 50/60 Hz) $17,500 – $21,000

Mobile Metal Cabinet 800-CFM Vacuum Stratified Separator System, which features: Separator, control panel with a programmable computerized LED keypad vacuum control operation. Feeder, Feed Hopper, a complete turn key operation. (Up to125 lbs. Per hour depending on species)

Excludes: Crating, Shipping and Handling

Crating Cost approximately: $165.00 -$475.00 (Depending on model)

PRICES EXCLUDE CRATING, SHIPPING & HANDLING.

Approximate price depends upon accessories, style or type, voltage and seed specie. Prices vary depending upon multiple options. On large units, request for prices.