Light Care

Simple tips to save money and increase production.

In your greenhouse, reflectors and bulbs become dirty but like anything they also wear with age. Timely maintenance of your supplemental lighting system is important to ensure you maximize your potential light and productivity. Here are a few simple steps to maintaining your

P.L. Light Systems installation:

CLEAN YOUR COMPONENTS

Even though the dirt may not be visible, it is very important to clean your bulbs and reflectors once a year. Regular cleaning is very important to ensuring maximum life of your investment. For cleaning instructions, please contact our technical experts at any time.

HAVE YOUR BULBS TESTED

A bulb should be changed after 10,000 to 12,000 hours of use. For every 1,000 hours, the useful light output decreases by 1 %. After 10,000 hours, 10% of your light output has been lost, but you’re supplying the same amount of electricity and lowering production.

In order to prevent loss in production, we can test the PAR or Lumen output of your bulbs in our Light Care testing facility. Our team of professionals will provide a thorough assessment as to whether it is cost effective to replace your bulbs.

HAVE YOUR REFLECTORS TESTED

Although you may not be able to see depreciation in light levels, your reflectors may be blocking as much as 10% of the light generated from the bulb. Lower light levels and uniformity will reduce your crop production and quality.

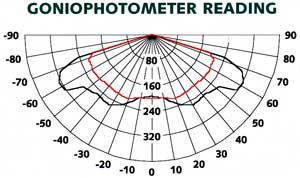

Depending on the greenhouse environment, a reflector is most often ready for reanodization, an inexpensive preventative maintenance technique, after 5 to 7 years. Using our Goniophtometer, we can scientifically measure the efficiency of your reflector and provide a useful analysis as to whether reanodization is the best choice.

HAVE YOUR CAPACITORS TESTED

Over time, a capacitor’s ability to sustain and balance power will decrease, which can cause issues with breakers tripping or conductive heat issues. An imbalance in power can be a source of useful light loss and therefore, production loss.

Our Light Care testing facility will take a capacitance measurement of your capacitors and provide an analysis as to whether replacement is necessary.

MORE LIGHT, LESS ENERGY STRATEGIC PROGRAMS TO

INCREASE EFFICIENCY, SUSTAINABILITY AND ASSURANCE.

The Ulbrich Sphere can test the lumen/PAR light output of any bulb.

This polar graph shows the difference between a used PL94 Medium reflector and a re-anodized one. The red line shows that the used reflector is operating at 90.7% of the re-anodized reflector.

At P.L Light Systems, we take a scientific approach to optimizing the PAR light in your greenhouse, so you can maximize your profits. That is why our LightCare team was created.

You want to know that your investment is operating in the most efficient way. You also want to ensure the longevity and quality of your lighting installation. We can help you with that. Our LightCare team offers expert service and professional maintenance advice to help save you money in the long run. Knowing helps. LightCare provides the knowledge and information to make it easy to achieve higher efficiency.

- Field Testing/Light Audits

- Laboratory Testing for reflectors, bulbs and capacitors

- Service Contracts

- Efficiency Assurance

If you are unsure as to the actual condition of your components, we can test just a few samples, deliver you precise data, and help you make the decision that’s right for you.

P.L. LIGHT SYSTEMS IS YOUR LIGHTING SOLUTIONS PARTNER

As the leaders in the greenhouse supplemental lighting industry for over 25 years, we have researched and developed smart and efficient ways for you to not only maintain the light level you purchased but also enhance it by bringing today’s bulb and reflector technology to your older, reliable, system. Find out how we can help maintain and maximize your light’s potential.