Cone Exhuaust Fan EC 50

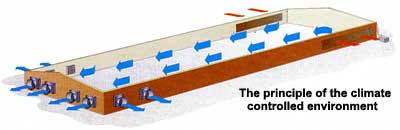

USGR offers a wide variety of exhaust fans for many industries, engineered, designed and priced to meet all climates of the world.

The unique propeller design is self-cleaning and allows the highest efficiency to be reached, while the discharge cone boosts the airflow dramatically:

The square fan housing, cone discharge and air conveyor (venturi) are mode of a strong galvanised sheet-steel. The 3-blade, propeller is statically and dynamic balanced for low noise and low vibration. The propeller is available in stainless steel, galvanised steel and precoated. galvanised steel.

To improve aerodynamic efficiency and reduce pressure losses the cone fan design has been developed in Munters euroemme’s R&D lab. The test chamber has been built according to ANSI / AMCA 210-85 Figure 5 specifications. Construction details and airtightress have been verified by

personnel of the BESS Lab at the Agricultural Engineering Department, University of Illinois USA.

Propeller, Cone Discharge and Shutter

The shutter is made of galvanised steel for all models. which is stronger than aluminum and plastic. The fan shutter is tightly closed when the fan is not working preventing any air leakage through the fan. The patented centrifugal system prohibits the shutter from being closed by air pressure, keeping

the efficiency of the Ian at a peak at all times by keeping the shatter fully and firmly opened. The shutter does not have to be cleaned regularly as dust does not affect its opening and closing movement. All the plastic parts are made of acetalic plastic with UV, protection.

Equipment

- Fan housing, cone and venturi made of strong galvanised sheet-steel

- Shutters are made of pressed galvanised steel in order to assure highest strength

- Each motor is individually tested for 100% quality control

- Central hub and v-belt pulley are made from diecast aluminium

- Optional belt-tensioner available for increased v-belt life and reduced maintenance

- 3-blade propeller is statically and dynamically balanced

- Shutter bearings are maintenance free

- Patented centrifugal system permits a fully and firm opening of the shutter

- Shutter is opened by rotating weights placed over centrifugal system arms

- Shutter opening is not affected by the weight of dust deposited on shutter blades

- A powerful couple of springs keep the shutters firmly closed when the fan is not operating

- Every fan is individually checked for quality

Order Information

EM50-X-X-X-X-X e.g., EC50-b-2-wm-wCEm-wt

- b : Code for electric motor according

to above table. - 2 : Code for the type of propeller blades.

- Galvanised propeller blades.

- Precoated propeller blades.

- Stainless steel propeller blades.

- wp-wm : Options codes

- wm: Fan delivered with pyramidal shape mesh for CE protection on shutter side.

- nm: Fan delivered without pyramidal shape mesh for CE protection on shutter side (standard)

- wCEm: Fan delivered with CE mesh on outlet side (standard)

- nCEm: Fan delivered without EC mesh on outlet side (standard)

- wt: Fan delivered with belt-tensioner.

- nt: Fan delivered without belt-tensioner (standard).

Motor Specifications

| EC 50 Code |

Nominal power | Type phases |

Speed | Frequency [hz] |

Voltage [V] |

Current [A] |

rpm | |

| [w] | [hp] | |||||||

| a | 735 | 1.0 | 1 | single | 50 | 230 | 5 | 1,380 |

| b | 735 | 1.0 | 1 | single | 60 | 220 – 240 | 5 | 1,700 |

| c | 735 | 1.0 | 3 | single | 50 | 230 / 400 | 3.5 / 2 | 1,400 |

| d | 735 | 1.0 | 3 | single | 60 | 230 / 400 | 3.5 / 2 | 1,700 |

| e | 1,100 | 1.5 | 1 | single | 50 | 230 | 7.3 | 1,400 |

| f | 1,100 | 1.5 | 1 | single | 60 | 220 – 240 | 7.3 | 1,700 |

| g | 1,100 | 1.5 | 3 | single | 50 | 230 / 400 | 5.2 / 3 | 1,360 |

| h | 1,100 | 1.5 | 3 | single | 60 | 230 / 400 | 5.2 / 3 | 1,700 |

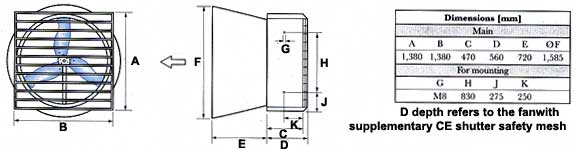

Technical Specifications

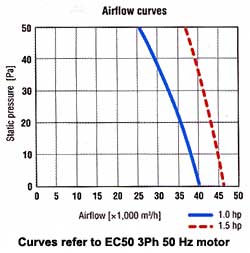

| 1.0 hp | 1.5 hp |

||

| Weight of fully equipped fan1 | [kg] | 106 | 108 |

| Nominal propeller speed | [rmp] | 455 | 565 |

| Airflow at 0 Pa1 | [m3/h] [cfm] | 40,420 [23,790] | 46,260 [27,230] |

| Airflow at 20 Pa1 | [m3/h] [cfm] | 35,650 [20,980] | 43,250 [25,455] |

| Specific performance at 0 Pa1 | [m3/wh] [cfm/w] | 38.6 [22.7] | 31.8 [18.7] |

| Propeller diameter | [mm] [inch] | 1,270 [50] | |

| Number of blades | 3 | ||

| Number of shutter blades | 10 | ||

| Max. operating temperature | [°C] [°F] | 50 [122] | |

| IEC protective class of electric motor | IP55 | ||

| Electric motor winding insulation grade | F | ||

| 1 Value refered to fan with tensioner and pyramidal mesh 3 phases 50 Hz motor. 2 All values refer to 3 phases 50 Hz single speed motor. N.B Airflow data are measured at standard condition (20 °C, 1013 hPa). |

|||

EM 50n is developed and produced by Munters euroemme S.p.A., Italy.