Euroemme Fans:

Jet Fan EMT30 – EMC30

Contact USGR for engineering and design

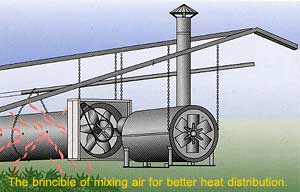

so that you will have efficient air movement, recirculation,

ventilation and heat distribution evenly throughout your building

EMT30 – EMC30

The unique propeller design is self-cleaning and together with air flow rectifiers. allows the highest efficiency to be reached

The housing and air conveyor (yenturi) are made of a strong galvanised sheet-steel. The 6-blade propeller is statically and dynamic balanced for low noise and low vibration.

To improve aerodynamic efficiency, the fan has been developed in Munters euroemme’s R&D lab. The test chamber has been built according to ANSI/AMCA 210-85 figure 15 specifications. Construction defails and dirtightness have been verified by personned of the BESS Lab at the Agricultural Engineering Department, university of Illinois – USA.

Propeller

Equipment

- Fan housing and venturi made of strong galvanised sheet-steel.

- Each motor is individually tested for 100% quality control.

- Central hub and v-belt pulley are made from die-cast aluminium.

- Propeller is statically and dynamically balanced.

- Special threaded bushes on fan’s side panels permit the fan to be easily hung.

- Every fan is individually checked for quality.

- By mixing the air, problems such as water condensation, crop disease due to high localised humidity, ammonia content in poultry houses, can be reduced.

- When operating in combination with suspended air heaters, the aid of the jet fan is powerful in reducing heating cost and for increasing the life span of plastic duct systems.

- EMC30, being equipped with motorised inlet shutter, allows more oxygen to be introduced into the house during mid season and winter months.

Motor Specifications

| EMT30 EMC30 code |

Nominal power |

Type phases |

Speed | Frequency [hz] |

Voltage [V] |

Current [A] |

rpm | |

| [W] | [hp] | |||||||

| a | 370 | 0.5 | 1 | single | 50 | 230 | 3 | 1,380 |

| b | 370 | 0.5 | 1 | multi* | 50 | 230 | 3 | 1,380 |

| c | 370 | 0.5 | 1 | single | 60 | 220-240 | 3.3 | 1,700 |

| d | 370 | 0.5 | 3 | single | 50 | 230/400 | 2.3/1.3 | 1,400 |

| e | 370 | 0.5 | 3 | single | 60 | 230/400 | 2.3/1.3 | 1,700 |

| f | 370 | 0.5 | 3 | multi* | 50 | 230/400 | 2.6/1.5 | 1,380 |

| g | 370 | 0.5 | 3 | multi* | 60 | 230/400 | 2.6/1.5 | 1,670 |

| h | 550 | 0.75 | 1 | single | 50 | 230 | 4 | 1,400 |

| i | 550 | 0.75 | 1 | multi* | 50 | 230 | 4 | 1,400 |

| k | 550 | 0.75 | 1 | single | 60 | 220-240 | 4.4 | 1,700 |

| k | 550 | 0.75 | 3 | single | 50 | 230/400 | 2.8/1.6 | 1,400 |

| m | 550 | 0.75 | 3 | single | 60 | 230/400 | 2.8/1.6 | 1,700 |

| n | 550 | 0.75 | 3 | multi* | 50 | 230/400 | 3.2/1.8 | 1,380 |

| o | 550 | 0.75 | 3 | multi* | 60 | 230/400 | 3.2/1.8 | 1,650 |

Technical Specifications

| 0.5 hp | 0.75 hp | |||

| Weight of fully equipped fan1 | EMT | [kg] | 43 | 44 |

| EMC | [kg] | 70 | 71 | |

| Nominal propeller speed | [rpm] | 590 | 640 | |

| Airflow at 0 Pa1 | [m3/h] [cfm] | 13,570 [7,990] | 14,680 [8,640] | |

| Specific performance at 0 Pa1 | [m/3Wh] [cfm/w] | 20.2 [11.9] | 17.8 [10.5] | |

| Propeller diameter | [mm] [inch] | 760 [30] | ||

| Number of blades | 6 | |||

| Max. operating temperature | [°C] [°F] | 50 [122] | ||

| IEC protective class of electric motor |

IP55 | |||

| Electric motor winding insulation grade |

F | |||

N.B. Airflow data are measured at standard condition (20 °C, 1013 hPa).

Order information

EMT30-X-X e.g., EMT30-b-2

EMC30-X-X e.g., EMC30-b-2

b code: for electric motor according to above table.

2 code: for the type of propeller blades.

- Galvanised propeller blades.

- Precoated propeller blades.

- Stainless steel propeller blades.