Very Important Some Valuable

Technical Information on Roses

CELdek® System Makes for

Cool Solution in Spain

Background

The Spanish companies of Roses EligFlor – Elig-Flor Castalla and Rosas Campello Obiol form a corporate group that has as its business the production of high-quality roses. The two member companies have production sites situated at Elche and at Castalla in Alicante city.

The group companies, as a whole, are firmly established in the Spanish market with a combined production reaching nine million roses a year. This makes the group one of the most important rose suppliers in Spain.

The total production of Elig-Flor is sold throughout the domestic market via the group’s own retail stores in the major cities of Spain (Madrid, Valencia, etc.). All the roses arc produced on nine hectares of land inside modern greenhouses having solid frames and employing a rigid plastic multitunnel system. The total number of employees within the group adds up to approximately 60 people.

Hot Problem

High house temperatures influence the plant performance negatively, and the resultant appearance of the roses tends to reduce the market price. The end result being lower profits during these summer months for the farmer.

Cool Solution

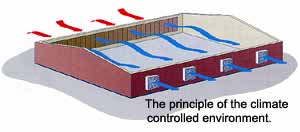

According to Rafael Obiol (General Manager, Elig Flor), Everybody in this business knows the benefits of a cooling system, but only the people who want to invest in quality actually end up installing it. By reducing the temperature in the greenhouses during the summer season, we are able to bring about an optimal growing process for the rose, thus obtaining the best product quality and appearance for the market. A good image of the product is very important, even as regards rose color and endurance, in order to obtain buyer satisfaction. With this system, which was designed in a cooperative project between Munters and Elig-Flor, the Group has been able to

- reduce the temperature inside the greenhouse by 6 °C

- increase the relative humidity to 72%. (‘This helps to dramatically cut water evaporation from the roses as they grow)

- retain high quality and appearance

- guarantee maximum profit.

An important point of influence is the shadow mesh installed inside the Group’s greenhouses, because this cuts out 60% of the solar radiation. Owing to this fact, the overall design was adjusted in consultation with Munters to match the optimal conditions using such a shadow mesh.

How Munters Does It

Installation Calculation

The installation in Elig-Flor’s greenhouses was calculated using on-site data, which included the amount of solar radiation falling on the greenhouse and the surface of the greenhouse.

Furthermore, 36 EDC24 units were installed in the greenhouses to prevent air stratification during the winter season. The purpose of this was to boost the expulsion of moist air and thus avoid the formation of dew on walls and ceilings.

Case Study

By installing the CELdek®

system the Elig-Flor Group has been able to:

- Reduce the temperature inside the greenhouse by 6 °C

- Increase the relative humidity to 72%. (This helps to dramatically cut water evaporation from the roses as they grow.)

- Retain high quality and appearance

- Guarantee maximum profit

- Improve the control of the house environment, and limit the temperature and humidity extremes