In Bench Heating Systems/

Under Bench Heating Systems

For International clients 1 KCal = 3.968 BTU

Delta – Tube™ SD EPDM Rubber Tube Bench Top Heating

Specifications:

The hydronic heating system shall be the Delta Tube TM SD EPDM rubber tube heaters using 135°F water temperature, and will consist of the following components:

- 1.0″ Manifolds with plastic adapters pressed fit into sch 80 PVC pipe cut to the bench width. All fittings shall be installed on top of manifold for easy connection of tubing.

- Ridged plastic spacers with spaces every 1 inch to hold EPDM tube in place and space tube on 6 foot spacing. Spacers shall be cut to bench width up to 8 foot long.

- High quality EPDM rubber tubing 0.177″ ID x .30″ OD shall be on ___inch centers. Tubing shall be able to resist ozone, chemicals, fertilizers, and temperatures up to 230°F. Tubing shall be provided on 1000 foot spools for easy handling.

Catalog No.3210 Effective 06/01/98

The DELTA-TUBE™ EPDM rubber tube heating system heats the greenhouse at the soil level where the heat is needed. Heat rising from the bench warms the soil and plant roots. By controlling the soil temperature both rooting and plant growth can be accelerated.

Tubing spaced 2 to 3 inches apart provides even temperatures to the soil and provides the optimum growing environment for propagators.

Seed germinators and plug producers have found that by heating the soil they achieve a higher germination rate and quicker production time. Growers have found times in rooting cuttings are reduced by heating the soil directly.

This system has proven to provide fuel savings of 20% or more over conventional forced air heating. Delta Tube EPDM rubber tubing is ideal for use in a hot water heating system due to its resistance to temperature and chemicals, and its superior heat transfer capabilities. Small tube design reduces water volume and enables the system to respond quickly and efficiently.

The Delta Tube manifolds use a unique plastic fitting that is pressed into the PVC pipe creating a water tight fit that is guaranteed not to leak. Each fitting is pressed into the top of the manifold so that the tubing is easily installed. Each manifold is custom manufactured for each system. The exclusive tubing spacers secure the Delta T tubing at the optimum design spacing. They are cut to the bench width for ease of installation.

Delta – Tube™ LD EPDM Rubber Tube in Ground Heating

- The hydronic heating system shall be the Delta Tube TM LD EPDM rubber tube system using 135°F water temperature, and will consist of the following components:

- 1.5″ Manifolds with plastic adapters pressed fit into sch 80 PVC pipe cut to the bed width. All fittings shall be installed on top of manifold for easy connection of tubing.

- Ridged plastic spacers with spaces every 2 inch to hold EPDM tube in place and space tube on 10 foot spacing. Spacers shall be cut to bed width up to 8 foot long.

- High quality EPDM rubber tubing 0.30″ ID x 0.45″ OD shall be on___ inch centers. Tubing shall be able to resist ozone, chemicals, fertilizers and temperatures up to 230°F. Tubing shall be provided on 1,000 foot spools for easy handling

Catalog No.3220 Effective 06/01/98

The DELTA-TUBE TM LD EPDM rubber tube heating system heats the greenhouse at the soil level where the heat is needed. Heat rising from the bed warms the soil and plant roots. By controlling the soil temperature both rooting and plant growth can be accelerated.

Growers that use our ground heating systems have shown 30% reduction of fuel usage along with shorter production times and superior product quality. This material excels in the nursery industry for general growing and rooting of cuttings and is ideal for starter houses. Growers that use this material for heating soil or nutrient bags of tomatoes and cucumbers have shown a 50% increase in yield. Grape growers have found a quicker and more even callusing pat tern by using bottom heat to callus grape stock.

Delta Tube EPDM rubber tubing is ideal for use in a hot water heating system due to its resistance to temperature and chemicals, and its superior heat transfer capabilities. Small tube design reduces the system water volume and enables it to respond quickly and efficiently. Tubing spaced 4 to 6 inches apart provides even temperatures to the soil and the crop and the optimum environment for all types of growing.

The Delta Tube manifolds use a unique plastic fitting that is pressed into the PVC pipe creating a water tight fit that is guaranteed not to leak. Each fitting is pressed into the top of the manifold so that the tubing is easily installed. Each manifold is custom manufactured for each system.

The exclusive tubing spacers secure the Delta T tubing at the optimum design spacing. They are cut to the bed width for ease of installation. Maximum length is 8 foot.

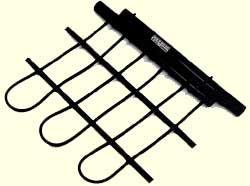

Delta – Fin™ TF Under Bench Fin Tube

Specifications:

The radiating material shall be the following components manufactured by Delta T Sales, Inc:

- The Delta-FinTM TF1 (3/8″ fin) and TF2 (1″ fin) shall be ‘A” OD aluminum tube with two integral fins that run parallel to the tube. Each fin tube length shall have each end prepared to accept the DeltaTwistTM coupler provided.

- Each return loop shall be Delta Fin'” TF1 or TF2 bent to size based on required spacing.

- Connection to the main lines shall be a special barb connection made of the ‘/8″ TF 1 material (special bends and lengths are available).

- Coupling shall be external slip on compression style with two high temperature “O” rings rated for -60°F to 230°F. (Maximum pressure rating – 100PSI at 230°F) – coupler patent pending.

- Material shall be supported from bench frame using 16 inch “S” hooks that will support the fin tube without drilling holes through the fin.

Catalog No. 3310 Effecitive 06/01/98

Catalog No. 3310 Effecitive 06/01/98

The DELTA-FIN™ aluminum under bench heating system heats the greenhouse using water temperatures up to 230°F by heating the air around the fin tube and distributing heat through natural convection and radiation through the plants. The versatility of the materials allows the grower to put the heat where it is needed, at the plant level.

By placing our high grade aluminum under or around the crop to be heated, the tubing, warm from the water running through it, radiates to the soil, roots and foliage of your crop.

Because of the superior transfer capabilities of the Delta Finn” TF, even temperatures are maintained throughout the system and the growing media. The end result is an envelope of warmth around your entire crop which you, the grower, control. Two sizes allow for various design considerations:

- TF1 Two fin aluminum material with 3/8″ fins is ideal for climates that have low heat requirements or need closer temperature control like plug production.

- TF2 Two fin aluminum material with 1″ fins has the added surface area for more heat transfer for higher heat requirements. External coupling design does not restrict water flow through the system which allows for longer runs and more even heat. No low flow high flow conditions inherent of an internal coupler.

Some of the Many Advantages of the Delta Fin™ TF Systems Are:

- Light weight aluminum construction allows for hanging material from benches without special support.

- Rugged construction can be supported on 12 foot OC Hangers.

- External coupling technology for easy installation.

- Requires NO special tools for installation.

- Does not restrict flows like internal couplers.

- Does NOT require Tek screws to hold material together.

The hydronic heating system shall be the Delta Tube TM SD EPDM rubber tube heaters using 135°F water temperature, and will consist of the following components:

The hydronic heating system shall be the Delta Tube TM SD EPDM rubber tube heaters using 135°F water temperature, and will consist of the following components: Catalog No. 3310 Effecitive 06/01/98

Catalog No. 3310 Effecitive 06/01/98