MODINE OIL -FIRED UNIT HEATERS

Design Features

Maximum Performance, Comfort, and Efficiency

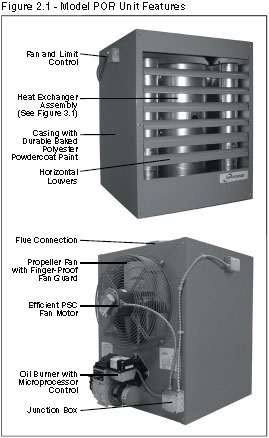

Modine model POR oil-fired unit heaters offer an efficient and reliable means of heating, particularly in regions where supplies of other fuels, such as natural gas, may be unavailable, undependable, or interruptible. The units are direct driven propeller fan type units designed for overhead suspension and horizontal delivery of heated air. They are available in three model sizes: 100,000, 145,000, and 185,000 Btu/hr outputs. Time-tested and field-proven components are engineered into the design of these compact units which produce comfort heating at the lowest cost through their highly efficient operation. Models are UL-listed and require fuel oil grade No. 1 or 2, as specified by ASTM (American Society for Testing and Materials) D396-73 Standard Specifications for Fuel Oils or Canadian Government Specification Board, 3-GP-28.

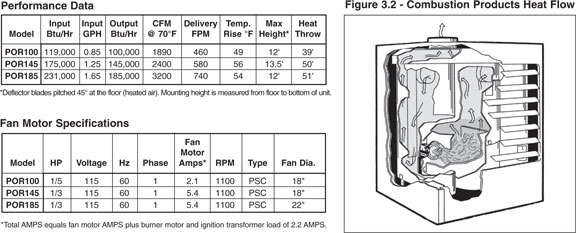

The following are standard features and benefits of the model POR unit (refer to Figure 2.1):

Advanced Burner and Burner Controls

Advanced Burner and Burner Controls

The POR oil fired unit heater is equipped with the latest in burner and burner control technology making the POR an industry leader in efficient fuel handling. Features include:

- A pressure-atomizing, gun-type burner with a stainless steel, die-stamped flame retention head that produces a highly stable flame with 20-30% greater combustion efficiency over non-flame retention type burners. The flame retention head matches the flame to the shape of the heat exchanger for maximum heat transfer while ensuring a long life.

- A two-stage fuel unit for maintaining maximum fuel pressure delivery, even in high lift applications.

- the fuel unit utilizes an energy efficient permanent split capacitor (PSC) motor with ball bearings for reduced energy consumption, excellent starting characteristics, and reduced maintenance.

- The latest in oil burner controls with a solid state microprocessor based controller featuring:

- Interrupted-duty ignition that disables the spark ignition once the flame has been proven. This feature extends the life of the ignition system, reduces component noise, and saves energy over traditional controls that maintain a power consuming spark during the entire call for heat period.

- Limited recycle/limited reset feature to limit the accumulation of unburned oil in the combustion area.

- Communications port to enable communication with service instruments or data acquisition equipment.

- Diagnostic LED to provide service personnel an easy indication of cad cell resistance and operational status

(lockout, recycle, etc.). - 15 second valve-on delay provides a pre-purge mode that allows for clean starts and reduced maintenance.

- A cad-cell safety system de-energizes the burner controls if a flame is not produced in 30 seconds. Manual reset of flame protection is required following this safety shut-down.

- Beckett electronic oil igniter module that provides superior spark ignition (20kV peak) and a smaller and lighter package than older spark transformer designs.

- Beckett CleanCut burner pump with the following advantages:

- Cleaner operation by use of a solenoid valve that cuts oil flow almost instantly when power is cut to the motor, eliminating coasting stops that can cause soot formation on shut-down.

- Pre-purge type controls work hand-in-hand with the CleanCut pump to establish airflow and bring pump pressure up to full operating levels before light-off to ensure smooth and clean ignition.

- More reliable with fewer moving parts, compared to conventional pumps and fewer troublesome oil fittings to cause problems.

Durable Attractive Casing Design

The casing is treated for protection against corrosion and painted with an attractive, Modine Gray-Green, baked polyester powdercoat paint finish.

Quiet, Efficient, and Safe Air Mover

The propeller fan is statically balanced and the motor resiliently mounted to the finger-proof fan guard to minimize vibration and noise. Additionally, the draw-formed casing venturi at the air inlet is designed to reduce fan noise and power consumption. The motor is a totally enclosed, permanent split capacitor (PSC) type that provides excellent starting capabilities with low amp draw on operation.

A fan and limit-control safety device performs three functions:

- delays start of fan until the heat exchanger has warmed up and prevents fan from stopping until the heat exchanger has cooled.

- protects the unit from overheating.

- provides a manual switch for constant fan operation.

Effective Heat Throw

Heat throw and coverage are controlled by manual adjustment of standard horizontal and/or optional vertical louver blades. Depending on the model, the heat throw will vary from 39 to 51 feet, maximizing heated air distribution at floor level.

Design Features and Performance Data

Superior Heat Exchanger Life Expectancy

Long life is due in part to the roll-formed design of the heat exchanger. Stresses caused by thermal expansion and contraction typically concentrate in areas of sharp angular bends or adjacent to welds, all of which are minimized with roll-forming to distribute thermal expansion stresses uniformly. Made of corrosion-resistant, 14 gauge aluminized steel, the heat exchanger contains a preformed, ceramic fiber fire pot that is thermally efficient, lightweight, resilient, and resists both mechanical and thermal shocks. It reaches operating temperature quickly, contributing to the efficiency of operation.

Efficient Combustion

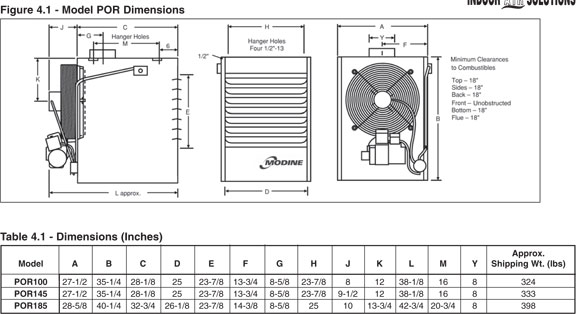

Combustion products heat flow through the heat exchanger can be traced by the arrows in the cross-sectional view in Figure 3.2. Flue products rise to the top of the drum, then pass into the two radiators of the heat exchanger where internal baffles cause them to flow to the bottom of the radiators; then back up to the flue collector and out of the stack. During this passage the original temperature at the fire pot of 2200-2300° F, is reduced to a stack discharge temperature of 470 to 570° F. The units are designed to operate at a stack draft of minus 0.02” W.C.

Easy Installation

All units are factory-assembled, wired, and fire tested prior to shipment. Units are ready to connect to 115V/60Hz/1ph supply voltage, a 24V thermostat, fuel lines, and vents. Units are shipped for a single-unit two pipe oil supply system, but can be simply modified for a single pipe oil supply system or a multiple-unit installation supplied by a common fuel distribution system. They can be suspended with four threaded rods (1/2”-13NC tap) or with 3/4” pipe by use of an optional pipe hanger kit accessory.

Reduced Maintenance, Easy to Service

Under average conditions Modine unit heaters typically require inspection only once a year, more often if the air is contaminated with fumes, dust, or spray.

The heat exchanger is equipped with a convenient inspection port and the service door opening is ample in size to facilitate the removal of the fire pot should replacement become necessary. Two clean-out ports are also readily accessible for periodic cleaning. Refer to Figure 3.1.

The motor is totally enclosed with permanently lubricated bearings to minimize maintenance. The fan and limit control, motors, and burner are externally mounted on the unit for easy service access.

Application Suggestions

Accesories

- Low-Voltage Thermostats – Single-stage, 24-volt.

- Thermostat Guard – Protects from damage or tampering.

- Booster Pump Relay – Used to control booster pump operation in the oil supply system. Factory set to close contacts at 50 PSIG with a maximum allowable pressure of 150 PSIG. Supplied with a 1/8” MPT connector and screw terminals.

- Oil Safety Valve – Protects the burner pump from excessive line pressure. The maximum inlet pressure is 60 PSIG.

- Fuel Oil Filter – Protects oil burner from foreign particles.

- Vertical Louvers – Used in combination with standard horizontal louvers for complete control of air delivery.

- Draft Regulator – Barometric type with screw adjustments and hinge-pin action. Designed for precise control of drafts.

- Outside Combustion Air Kit – Kit converts the burner to accept outside combustion air piping. Includes adapter, gaskets, vacuum relief valve, outside intake air hood, and other miscellaneous hardware.

Advanced Burner and Burner Controls

Advanced Burner and Burner Controls