Sioux Steam Flo®

Soil Sterilizer

Soil Steaming

Using a commercial soil steamer is a highly effective way to prepare soil in your greenhouses, high tunnels, or open fields for planting. It uses steam to rid the substrate of fungi, diseases, invasive species, weed seeds, and other harmful biological materials. Using steam before planting gives you larger, healthier plants with improved yields.

How the Sioux Commercial Soil Steamer Works?

Sioux’s various sized commercial steam generator models produces 370-3,450 lbs. of steam per hour. A steam sock and tarp allow you to deliver steam evenly to the area. Smaller Sioux steam generators heats a single 20′ x 100′ section of soil up to 180° Fahrenheit (82° C). Multiple sections can be heated simultaneously with larger models.

We recommend that you allow the soil to remain at 170°-180° Fahrenheit (76°-82°C) for a minimum of 30 minutes. Sustaining this temperature range for at least half an hour removes:

- Weed seeds

- Harmful pathogens

- Nematodes

- Other contaminants

Simple to Operate

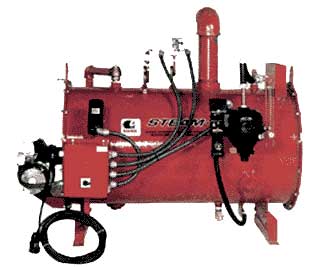

Model SF20. Model SF25 is

same model using gas fuel.

With few moving parts, the Sioux Steam Flo® Soil Sterilizer is simple to operate. The unit can be quickly moved into place, and can be ready to go in just minutes. Simply connect your water supply, plug into electrical and the unit is ready to go.

Quick, Continuous Steam

Steam at full operating pressure is available only 20 minutes from a cold start. After start-up, the Sioux Steam-Flo® steam generator provides a continuous supply of steam; there is no recovery time. The Sioux Steam Flo® produces 368 lbs. of steam per hour, 5 to 10 PSI operating working pressure, burning 3.05 gallons of fuel per hour.

Rugged Design

The Sioux Steam Flo® vessel is constructed from 1/4″ boiler plate all-welded steel, and will give years of service with minimal maintenance. Low water sensor switch and automatic water feeder maintain the proper water level automatically and shut off the burner if water falls below safe levels.

Portable

Mounted on wheels with 15″ pneumatic tires, the Steam Flo® can be moved by hand or truck to any location, inside or out. Trailer hitch is provided. With extra hoses, you can effortlessly provide steam for hard-to-reach places. The unit requires only 37 square feet of floor space, so soil steaming or steam generation can be done almost anywhere.

The Sioux Steam-Flo is a perfect source of low pressure steam for a variety of commercial and industrial applications. This unit can be used in place of a conventional boiler for a variety of commercial and industrial applications. The generator produces 370 to 845 lbs. per hour of saturated steam in minutes. The Steam-Flo provides continuous, unlimited steam. The unit is easy to maintain and built to last. Mountings include portable, stationary, or over the road trailer. Unit can be outfitted with optional water tank and generator for completely self-contained operation. Because of its portability, the Steam-Flo is excellent for use in overflow production and outlying area.

Steam-Flo generators are often used in commercial greenhouses, nurseries and industrial applications including heating steam jackets and thawing pipes and valves. Thousands are in operation worldwide, providing years of trouble-free service.

The Sioux Steam Flo® is built to stringent ASME (American Society of Mechanical Engineers) Code requirements and is permanently registered with the National Board of Boiler and Pressure Vessel Inspectors. The unit is hydrostatically factory tested and inspected to 60 PSI.

Low Maintenance

With few moving parts, the Steam Flo®‘s simple design is virtually maintenance free. Many units sold over 20 years ago are in use today.

Modular Units Provide Cost Savings

Since the Steam-Flo® does not require extended fire-up time, you can save money by operating the unit only when steam is needed. Chemical usage can be minimized or eliminated. When not in use, the unit can be wheeled away to a storage area. Two or more Steam Flo® units can be used together to provide extra output for sterilizing or heating. The Steam Flo® soil sterilization equipment offers flexibility and portability that large, permanently-installed equipment cannot provide.

Proven Dependability

The first Steam Flo® was sold over 35 years ago, and units are serving in a variety of industries around the world.

Available Options

- Steam tarp is available (specify length and width).

- Steam hoses of various types and lengths are available.

- All fittings are available, depending upon application.

Standard Construction

| Boiler Horsepower | 10.67 |

| Steam Output ( 212° F. Inlet) | 355 LBS/HR |

| Firing Rate, #2 Fuel Oil | 3.05 GPH |

| Input BTU PER-HR | 427,000 BTU/HR |

| Maximum Steam Working Pressure | 15 PSI |

| Operating Steam Working Pressure | 5 – 10 PSI |

| Maximum Temperature | 250° F |

| Heating Tube Surface Area | 49 FT2 |

| Approximate Machine Dimensions (Leg Mount) | 60″L x 40″W x 51″H |

| Approximate Machine WT. (DRY) | 900 LBS |

| Approximate Boiler Volume | 55 Gallons |

| Optional Fuel Tank Capacity | 36 Gallons |

| Approximate Efficiency | 84% |

| Boiler HP | 10.3 |

| Steam Output (212° F Inlet) | 355 LBS/HR |

| Approximate Insulation Cost pay back period, Based on 1000 HR/YEAR Operation | 2.2 Years |

All specifications are based on standard operating conditions and may vary +/- 5%. Prices on request.

Options

- Portable Non-highway Trailer Option:

- 15″ Pneumatic Tires

- Trailer Hitch

- 36 Gallon Fuel Tank

- GFCI Electrical Cord and Plug

- Over the Road 2 Wheel Trailer

- Skid Mounted with 36 Gallon Fuel Tank

- Insulation Option:

- 1″ Fiberglass Based

- Protective Stainless Steel Outer Wrap

- Available as a hot Water Boiler