HEATERS AND HEATING SYSTEMS TECHNOLOGY

For International clients 1 KCal = 3.968 BTU

We select systems from each manufacturer that helps our client the most. Naturally, each heating manufacturer feels their products are best and they market what they produce.

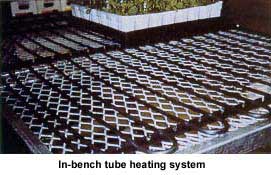

As we are worldwide, we offer all types of heating systems for agriculture, product storage, warehousing, etc. We offer and are agents for both domestic and international manufacturers to include the outstanding Tecnoclima Company and the famous Euroemme/Munters/Aerotech heating systems. Domestically we offer the Lonnox/True Leaf, Modine, ADP and the ERMAF heaters. We also offer the Siebring heater which is a reliable floor mounted unit. The outstanding in-bench neating system comes from Delta-T and we highly recommend Delta-T for those growers propagating and growing crops on benches.

No singel heating company manufctures systems for every type of fuel,heating requirements as tot eh amount of heat, nor do they offer distribution of heat for all requirements. There are many reasons why we utilize different heating companies for differnet applications. Some heating companies such as Tecnoclima offer systems for all the voltages of the world. Other companies may offer only 50 cycle or 60 cycle. there are also many different priced units. Some systems are adapted for air delivery systems, others for boilers and piping. Other systems, such as Delta-T are for on and under the bench systems. The requirements worldwide are so diverse, we must offer many companies heating system to meet our clients’ crop and temperature needs. Some of the companies we represent are Tecnoclima, Modine, Lennox/True Leaf, Delta-T, Munters, Euroemme, ADP, ERMAF/True Leaf, Siebring.

Each client has special needs and requirements; there is no correct or right way to implement a heating system – availability of fuel source,heating requirements, delivery system, cost, crop grown, climate conditions,etc. can all enter into your final decision and there are benefits and disadvantages to every system.

We have descriptions of some of our most popular heating units on the Heaters and Heating Systems page.Please visit it.

We hope we have the opportunity to serve you.

TYPES OF HEATING SYSTEMS

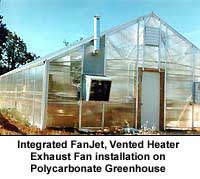

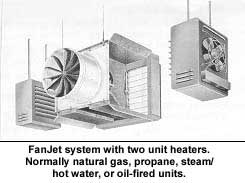

The most popular and economical and the easiest to operation and install are the air delivery systems utilizing Unit Heaters, generally suspended. These units blow hot air throughout the greenhouse, or are connected to Fan-Jets.

Unit Heaters are cheaper to buy in small numbers than Boilers and when used with Poly Ducts or Fan-Jets, heating is quite even throughout the house. The limiting factor is about 450,000 BTUH per house for one duct. If heat requirements are greater then space units or perimeter heat must be added.

Boilers are the choice in many parts of the world. Furnaces are usually fired either with Oil or Gas burners, Water/Steam is the transfer medium using either pipe or Blower Units. Smaller, individual package boilers are becoming very popular.

Finally, a word on propagation and on Bench Heating. These systems are rapidly gaining acceptance for their energy savings and because they put the heat where it does the most good: in the canopy of the bench-grown plant. They are efficient and warrant consideration for bench or floor grown, low height plant production. They have their limits in colder regions and where total air heating is needed. Costs very dramatically, depending on many factors.

SELECTING A HEATING SYSTEM

Some basic information is necessary to even begin to assist our clients:

- Size and type of building, Greenhouse, warehouse, industrial building,poultry, hog, farm building.

- Type of covering

- Crop to be grown

- Lowest outside temperature in winter

- Average outside temperature in winter

- Existence of unusually high wind conditions (we generally use 15 mph wind speed in our calculations)

- Bench or ground grown crop

- Voltage and electrical information

- Your choice of energy source

- Do you have a standby generator?

-

Dimension of building.

Heaters available from:

- Tecnoclima

- Munters/Euroemme/Aerotech

- ADP

- ERMAF/True Leaf

- Modine

These initial questions will help us in providing you with some support.

Unfortunately, we cannot select for you. Many prospective clients ask us to give cost and technical design or 3 or 4 systems. To do so is both expensive and time consuming. Consulting and Technical Assistance is available to help determine which fuel source you should use; the cost is nominal, butmost clients determine their own fuel sources as soon as they decide to build or expand., and we assist in selecting most economical, efficient, and proper installation

OUR EXPERIENCE

The following indicates a 45 year history of our projects as pertains to the most used energy sources.

- Natural Gas Air Delivery UnitsNote 1

- Propane Air Delivery UnitsNote 1

- Steam/Hot Water Units connected to client owned BoilerNote1

- Package Boilers connected to greenhouse piping systems

- In/Under Bench Heating Systems using tubes and small boiler.

- Fuel Oil Fired Unit Heaters

- Purchased Boilers for clients and supply heat to the greenhouse

- Geothermal (only if water is in excess of 140oF(60 C) at wall of greenhouse

- Electrical for small institutional greenhouses or chambers (only on rare occasions)

- HVAC Units for institution and industrial units when required (only 5 systems in 10 years)

IN FLOOR HEATING SYSTEMS ARE BECOMING MORE POPULAR EACH YEAR – CONSIST

OF HEAT PIPES PLACES IN CONCRETE FLOOR WHEN PLANTS GROWN LOW OR ON FLOOR.

NO PICTURES, BUT WE WORK WITH A FIRM WHO CAN HELP YOU DESIGN AND IMPLEMENT

IDEAL INSTALLATION.

Note 1Most often connected to Fan-Jet system of Fan, Shutter, Tubing, and Head Distribution chamber.

We have descriptions of some of our most popular heating units on the Heaters and Heating Systems page. Please visit it.

SPECIAL NOTE ON GAS OR OIL FIRED UNITS

When using Gas or Oil Fired Units in the building, proper venting is essential.If you see signs of epinasty, bud damage, or other crop problems, or if you smell exhaust fumes, then these are indicators of improper venting.Good and complete venting of the units is most important.

ABOUT THERMOSTATS AND THERMOMETERS

Another word of caution: we have seen hundreds of times where growers spend great sums of money on efficient heating systems and then install $2.00 USD thermometers and cheap thermostats that are not accurate. You may think you are growing at 65oF (17C) when the actual temperature is higher or lower by 2-3o– not much difference for one day, but a tremendous amount over a 3-4 month winter.

Also, be sure to install the thermostats and thermometers so they can raised or lowered. So often we see them hung at eye level when the crop is grown on the ground. Put them where they are needed – at crop level.

Maintenance is a very important part of your heating system. For our clients we provide materials to assist you. On request with purchase we will supply our tips on maintenance, operations, and heat savings techniques.

INTERNATIONAL RATING ADJUSTMENTS

Most of our literature is published based on 60 cycle power. Many international markets use 50 cycle power, and therefore unit power capabilities must be adjusted by the following rules of thumb. Check with local electricians for all conversions.

- Gas Fired Heaters / Oil Fired Heaters:

- Multiply catalog / web site BTU input and output by 0.833

- Multiply catalog CFM by 0.833

- Hydronic Unit Heaters – Steam/Hot Water

- Multiply catalog BTU output by 0.896

- Multiply catalog CFM values by 0.833

- Also CMH (Cubic Meters per Hour) equals 0.588 CFM (Cubic Feet per Minute)

Our international clients using single and three phase 50 cycle instead of 60 cycle would find that the following are available from stock. All types of heaters, Tecnoclima, Euroemme, Ermaf.